First visits

21st March

Up early and on the road at 6am!

Kailash (our supplier in Rangisthan) took us from Jaipur to view sandstone quarries in the Kotah district some 250km from Jaipur. We passed through Bundi on the way. Traffic in

It was obvious when we arrived in a stone area: the road wound up a bare stony slope to an arid plateau some 50 metres higher than the greener countryside that we had been travelling through. It was clearly drier and the nature of the agriculture changed.

We began to see the first of the dry stone walls that we would see throughout the entire area, dividing up fields. We also started to see more and more stone buildings. Some of the stone walls and buildings were beautifully and precisely built and we could see that some of the stone buildings were rendered and painted.

We arrived in a village and picked up the second of the two buyers that work for Kailash in the area (we had picked up the first on the way nearer Jaipur). We were now at the fringe of an area covering approximately 40 square kilometres and home to 1,000 sandstone quarries.

On either side of the road we could see various businesses that split quarried block and cut paving. These businesses varied in size from small operations occupying a fraction of an acre to a few quite large operations with several acres of open space. We saw empty wooden boxes stacked up ready for packing as well as full boxes. From our car it was difficult to clearly see all of the people working in these areas but I did not see a single woman or child working in these businesses.

We turned off the main road and, following the directions of Kailash’s buyer, drove toward a cluster of quarries. At first the only evidence of quarrying we could see was a small hill of overburden perhaps 30 metres high. As we approached the quarries, we drove past a primary school with children in school uniform playing outside. We asked our driver if it would be possible to stop at the school on the way back from seeing the first quarries.

First Quarry:

A kilometre or so further on, just past the hill of overburden, we suddenly arrived at our first quarry. We drove down and parked on a flat area about 3 metres below the level of the surrounding ground. Looking at the sides of the quarry we could see that the uppermost 2 metres was soil and then a metre or so of stone that was made up of boulders of various sizes and quite fractured bedrock. From this level down the bedrock was more continuous down to the level of the quarry floor about 3 metres lower than where we were standing, some 5 metres below ground level. Stone was being recovered from the lower 2 metres of the quarry, working back toward us. There was a small mobile crane used for lifting the blocks as they were recovered and for stacking them ready for transport. There was also a tractor driving an air compressor with hoses snaking across to the rock drills.

The stone is recovered layer by layer from the floor of the quarry. Firstly, rows of holes are drilled to outline the next block to be recovered from the face. These holes are drilled about 20cm deep into the stone and are spaced about 20cm apart. I watched for a few minutes as three workers drove wedges into the holes and hammered them home.

When this was done they used an 18 pound (8kg) sledge hammer to finish setting the wedges and separating the block.

Each of the three workers took a turn with the sledge hammer hitting each wedge along the row before passing the hammer on to the next worker. When the third worker was about halfway along the row there was a sound like a single short note on a bass drum and a crack appeared along the line of the wedges.

This whole process from putting in the wedges to separating the block weighing 6-8 tonnes took only 5 minutes. While I was taking photos Dave asked the quarry owner about the ages of the workers and was told that the youngest was 25 years old. We asked how many of the 1,000 plus local quarries were illegal and were told none. We asked about child labour and were told that there is no child labour, the work is simply too hard or too skilled.

At this quarry only block was being recovered. The blocks were being picked up by a crane and stacked ready for loading onto trucks. This quarry was a source of the block that was being trucked back to Jaipur for processing into the paving, cobbles, sawn elements, and other value added products sold by Rock Unique.

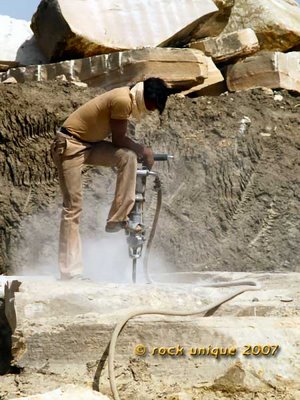

We spent a while longer at the quarry watching the floor of the quarry being drilled. The compressor for the pneumatic drill was powered by a tractor on one side of the quarry with air lines running to the drill on the other side. The worker operating the drill was wearing sandals and had a cloth across his face. The drill was relatively noisy but very effective; it was sinking into the stone quite rapidly, taking about a minute to drill each of the holes.

We asked about steel capped boots, ear protection, face masks, safety glasses, and health and safety in general. We received the same answer every time we asked this question throughout the day, that safety equipment is readily available for the workers but is simply not used.

At the edge of the quarry some blocks had been erected vertically to create walls and large flat slabs placed on top to make a shelter. There is very little shade in a quarry and these shelters are built to provide a place in which to take a break out of the sun.

Second Quarry:

We were told that this quarry was still relatively new, so we asked if we could see a quarry that was more developed. We were driven a very short distance to the quarry next to the big waste pile that we noticed earlier. On the way we had more of a chance to view the site where stone was being split into paving.

The second quarry was immediately next to the hill of spoil that we could see as we approached the area. It was only when we turned onto the road leading into the quarry that we began to see how deep down this quarry had gone. This was where the hill of spoil had come from. We parked near the top; there was work being done next to the road and it wasn’t possible to drive down to the floor of the quarry. This quarry was much more mature, having penetrated deep into the bedrock and blocks of grey sandstone was being recovered from a level about 20 metres below the surface. There were about 40 people working on site. In a period of fifteen minutes we saw three blocks separated and removed from two areas along the working face of the quarry. The working area was very clean and clear of debris.

There was a tractor driving the compressor for the pneumatic hammer drills and another with a trailer for carting away the debris. Each block was first separated with wedges as we saw in the previous quarry and then manoeuvred using crowbars so that a chain slung from a crane could be used to lift the edge of the block. A lump of debris rock was placed under the block for support to enable the chain to be manually slid up to the mid point and then the block was lifted out.

The crane operator was very skilled; he stacked the block to one side, the chain was unhitched as soon as it became slack and he went back to collect the next block. The quarry manager came to talk to us and we were told that the average pay had risen steeply over the last few years to INR10,000 per month (about USD250) from INR6,000 per month 3 years ago. When asked how many people were injured or killed in the quarries each year, he said only 3 or 4. I think that he meant injuries only as we later discovered that there had been zero fatalities in this area over the last few years.

This quarry was a much larger operation and there was more heavy equipment in use. We saw a truck-mounted drill being used to drill long lines of holes deep into the bedrock.

This method of working was described as being much more cost effective than using hammer drills. Dump trucks were being used to carry the spoil to the hill at the far end of the quarry.

I saw two women in the quarry; their job was to take water and tea to the workers throughout the day.

The overall impression was of a well-run business using skilled labour and the best available techniques and equipment.

We then drove back to the school that we had spotted earlier, a two room government primary school, painted pink on the outside and blue on the inside. We went in and spoke with the head teacher who gave us permission to take photographs.

The teacher said that the parents of many of the children worked in the stone business. There were two teachers and I counted forty children.

Third Quarry:

Leaving the school, we drove on to look at more quarries. As we travelled, we saw fields that had loads of soil dumped on them. I was later told that this fertile topsoil had come from quarry overburden and was being spread over fields, especially those that had exposed bedrock or very thin soil with the intention of improving the agricultural potential of the land.

We also saw more schools, most of them with just one or two rooms.

Eventually, we arrived at a very large quarry where hundreds, if not thousands, of blocks were stacked up by the road that wove between them and we made our way to the part of the quarry being worked.

As with the previous quarries, our visit was not expected. All the staff we saw in this quarry were adult and male, and again we saw sun shelters made of blocks and large slabs.

Fourth and final quarry this day:

We left this quarry and travelled to yet another very large quarry, passing many more small schools on the way. As we entered this new quarry, we again saw shelters made of block.

This quarry differed from the others as stone was being split into paving on site.

We could see the long lines of holes drilled by truck-mounted equipment.In this quarry the stone was being recovered not in blocks but in thinner slabs, often less than 10cm thick.This seemed to be because the stone was being split on site and slab was preferable to work with than thicker, heavier block.We could see that this thinner stone was sometimes fracturing as it was being recovered resulting in higher wastage rates.

The quarry owner claimed 500 people worked on the site. David asked the owner where the quarry workers children went to school and was told “at the government schools”. David then asked if these were the pink buildings that are painted blue inside to which the quarry owner replied “yes”. As we left, we could see that at least one other area on the far side of the quarry was also being actively worked.

After leaving this quarry we saw an area that had formerly been a quarry but had been back-filled and planted with trees, in the midst of which was a lake. Further on we saw two larger schools, which we were told that they were for older children; they looked like the local high schools.

As we were leaving the area we saw construction works for a dual lane highway, and told that this road would be running first to Bundi, the city that we passed on the way, and then on to Jaipur. We had averaged 50 km/h getting out to the quarries, it was very clear that a new road would make an enormous difference.

The first quarry we had visited was probably no more than 10 km from the last, in this area we saw at least 8 schools. Our visits were unscheduled and unannounced and in this one day we directly observed some 200 adults working in the quarries, including two women, yet we did not see a single child working in any of the quarries.