|

|

|

|

| Flags & Slabs - Page 05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fieldstone walks - Kerry Link - 27 Sep 2002 | ||||

|

I live on a 200 year old farm in North Carolina. There are many fieldstone walks and patios. When we bought the house, there was originally concrete or mortar between the stones. This was not only ugly, but failed to anchor the stones, as each winter the concrete/mortar cracked, broke up and eventually washed away or was removed.

We subsequently planted ordinary grass in between the stones. This gave a beautiful appearance but became a maintenace nightmare. Without weekly trimming, the grass soon crept over the stones and covered them. Considering there are hundreds of stone-stone interfaces, this became unmanagable. We are in the process of removing the grass. We wanted to know your suggestions on what to do to anchor the stones. We would consider replanting grass, if there were some variety that only grew to 1 or 2 inches, and would not require such intense care. We would consider other options, but are not keen on the idea of concrete etc. Our winters tend to be harsh with a fair degree of soil movement. We have tried sand and small rocks but both were quickly washed away. The stones have been in the ground for who knows how long and I am not sure how they were originally set. I suspect they were just put in the dirt. The large stones are hundreds of pounds, and have not been a problem with regards movement. However, the washout between them and the surrounding stones can be quite significant. The smaller stones, less than 100 pounds, are the problem children.

Thanks in advance for your help. |

|||||

|

|

Tony McCormack - 27 Sep 2002 | ||||

|

I'm not sure if 'fieldstone' means the same in North Carolina as it does in North Warrington, but to us, fieldstones are large, irregular lumps of local stone, and as such, they don't really require 'anchoring'; their mass is sufficient to hold them in place to foot traffic. However, I can understand you wanting the joints to be filled.

I can't suggest any small grasses, as the types/species we have in the UK and RoI are totally different to those in continental USA, and you are not impressed with the longevity or otherwise of cement-bound materials so.... You could use a grit or a small gravel, I suppose. This won't anchor the stones but it will be maintenance free. Or you could opt for a polymeric sand (see Alternative Jointing page) as that would fill the joints and keep them more or less weed-free, but again, it would not anchor the stones. If you want a permanent bond, then you need something flexible, perhaps a polymer system or an epoxy system, but I don't know what products are available in your country. If it were mine, I'd go for either the grit/gravel option, or possibly something a touch more decorative, such as slate waste, a tumbled coloured glass or even something dashingly modern such as ball-bearings!

Hope that gives you some ideas. |

|||||

|

Kerry Link 27 Sep 2002 |

Thanks for you input. Our fieldstones sound about the same. The smaller ones do come loose after constant rains if there is nothing in the cracks. The larger ones don't move, but the open cracks can serve to trip someone, if not filled. We've tried the grit/gravel but it also tends to get washed out. That's why we were interested in grass.

Kerry |

||||

|

|

|||||

|

Marshalls Standard Flags - Cath Howarth - 18 Oct 2002 | ||||

| BOUGHT FLAGS COSTING £300 A FEW MONTHS AGO. THE FLAGS ARE KNOWN AS "STANDARD C5O NATURAL PAVING FLAGS". THEY ARE POOR STANDARD AND BADLY MARKED AND CRUMBLING AT THE EDGES. IN FACT, THEY ARE AN EYESORE. MARSHALLS SAY THAT THEY ARE FINE AND NOT MEANT FOR DOMESTIC USE - THEY ARE MEANT FOR LOCAL AUTHORITY WALKWAYS! WOULD BE GRATEFUL OF ANY HELP AND ADVICE AS WE WISH TO TAKE THIS FURTHER. | |||||

|

|

Tony McCormack - 19 Oct 2002 | ||||

|

Marshalls generally have a good reputation and, if products are sub-standard, they are replaced without argument. Have you seen a rep from Marshalls or from the BM that supplied the flags to you?

C50 flags are 750x600x50mm and they are primarily 'targetted' at LA Highways work, but that doesn't exclude their use on domestic projects, nor does it permit a sub-standard product. In fact, large quantities of these standard flags are still used on newly built properties as the access paths around the building, so the suggestion that you have selected an 'incorrect' product for your project is spurious, to say the least. Take photos of the flags; get the comments made so far to be repeated, in writing by whoever made them, and put your concerns in writing to Marshalls HQ in Halifax (see Links Page for address). I've dealt with Marshalls for the best part of 30 years and I've never known them to reject a fair claim for sub-standard products: in fact, I've known them to replace products that were perfect, but it was easier for them to replace a few square metres of paving than to endure a long, drawn-out argument with a client that wouldn't know which way up to lay a flag in the first place. So, to summarise; establish exactly who made the comments you report, and get them to put them in writing. Take photos of the problems, and put in a claim to Halifax in writing, detailing just what you consider to be the problem and include copies of your photos. I'd be stunned if that didn't elicit a response. |

|||||

|

Cath Howarth 20 Oct 2002 |

Tony,

thanks for the reply. in answer to the questions:

we received a letter from marshalls to say the rep thought they were fine. we are currently in the process of writing another letter to Halifax office, as we are far from happy. the driveway cost over £400 to do, and they really need ripping up. the old flags were far better than the new ones. we want the money back for the flags, or replacement, or some contribution towards the cost of putting the driveway right. it should be noted that there was nothing written on the packaging explaining that the flags were not suitable, and no advice was given at the builders merchant. this will be sorted we hope, and we are seriously considering contacting watchdog or similar for advice. even if the flags were not meant for our use, then i wonder what they should be used for? they are an embarrassment and look horrendous. surely this is not good for marshalls??? we will let you know what happens. this is not the end.

thanks |

||||

|

Tony McCormack 20 Oct 2002 |

Do you have any photos? I can give you an impartial opinion, if you have piccies - my contact details are given on the About Us page. | ||||

|

David Sarti 22 Oct 2002 |

Cath,

I've emailed contact details to you directly. Please give me a call or email me with the precise quantity of units and I'll arrange free delivery of replacements.

David Sarti (ps - we do not monitor this site, or any other for that matter, I just came across you're posts whilst looking for some advice for myself!) |

||||

|

|

|||||

|

Pointing for beginners - Mark99 - 22 Oct 2002 | ||||

|

I posted a few weeks ago asking for advice on installing UFH under indian sanstone flags.

I am glad to report that the flags are now down, and the 190m UFH cable (ebeco) is in place! After some over complex calculations before we started we finished within 9 inches of the end of the room, not bad really, as the cable cannot be shortened! Anyway, I have not tested the system yet, so it is a nervous time, and before I can I have to point the flags. I have read the various posts regarding pointing, but I need some really basic tips as all this is new, and I do not want to spoil what so far has been a rewarding experience. So here goes. 1. I was planning on using a 3.1 mix for the pointing. Is this correct? 2. The sand I have is quite gritty, will this be OK? 3. Do I need to add Feb to the mix? 4. How do I stop from staining the flags with the mortar? 5. If I do drop mortar on the flags am I best waiting for it to dry and brush off, or use a wet sponge to attack it straight away? 6. Any other tips I need? Your advice last time was very useful, and was put into practice. As promised I have take loads of photos and will be sure to post upon completion!

Thanks in anticipation |

|||||

|

|

Tony McCormack - 22 Oct 2002 | ||||

|

Hi Mark,

taking your Qs one at a time....

3.1 mix for the pointing. Is this correct?

The sand I have is quite gritty, will this be OK

Do I need to add Feb to the mix?

How do I stop from staining the flags with the mortar?

If I do drop mortar on the flags am I best waiting for it to dry and brush off, or use a wet sponge to attack it straight away?

Any other tips I need?

Good luck! |

|||||

|

|

|||||

|

Millstone by Stonemarket - Mccandjt - 3 Nov 2002 | ||||

|

4 years ago, when friends had a patio laid in ""millstone" we were delighted to find such genuine looking flags on the market . We decided to flag our front path / driveway entrance and a small patio area at the back of the house as a trial (and to test our competence) before doing the rest of the driveway and larger patio area.

It took some time and squabbling - not to mention cash-but we got there! Passers by stopped to comment on the "good job" we were making and we even passed on the name of the product to two lots of admirers. We were delighted with our efforts and paving, and felt our money had been well spent. As the Stonemarket brochure promised, the flags look their best when gleaming with rain - and we certainly get plenty of that in Preston. The bad news is they now gleam for other reasons. The aggregate is beginning to show through on the edges of a large number of the flags (and those of the friends whose patio inspired us to follow suit) They are clearly fake! We're in a quandry - how do we finish the job? Despite the passing of 3+ years we still have unsightly grey hardcore linking front of house to back! Do we assume we and our friends got a bad batch of flags and quality control were having an off day and buy some more? Or is it likely any future supplies will look genuine only for 4 years so we need to find an alternative? Any thoughts on the subject would be welcome whilst we pen our letter to the company seeking its comments. |

|||||

|

|

Tony McCormack - 3 Nov 2002 | ||||

|

Although Millstone are probably one of the top 3 riven copies in the UK, they are still 'concrete' and no matter how well they are manufactured, nor how good the concrete itself is, nor how rich are the dyes, there's nothing you can do (short of sealing them after they are first laid) to stop them weathering and reverting to what they are...concrete.

I've seen it on several 'prestige' jobs where the flags have been down 3-6 years and weathering has resulted in the aggregate becoming exposed and beginning to show through. I'm not sure there's anything Stonemarket/Marshalls can do about it, or whether they'd entertain your complaint, but it's worth the cost of a stamp writing to them. These high-cost riven copies are now facing an uncertain market. Since they were first introduced onto the market a decade ago, the country has been flooded with cheap, imported riven stone that can compete with these copies in terms of price and it is now debatable whether a concrete copy at around 25 quid per square metre represents good value when you can get genuine stone for around the same price. OK; it's not true 'Yorkstone' and some of it is absolute rubbish, but there's some damned good stone being brought in that only anoraks such as meself would be able to spot as not being genuine 'British' stone. I think the coming year will be the 'breakpoint' when these 'premium products' will either have to drop their prices in response to the imported stone or offer something special that isn't available in the natural stone (yet). For the design work I do, I'm now at the stage where I'm suggesting clients would be better off using the quality genuine stone rather than these concrete copies. In 5 years time, the stone flags may well be green with algae, but they'll still be stone and can be cleaned up to look like new again, whereas the concrete copies will more than likely have weathered to look not too dissimilar to the cheap 'budget' concrete copies sold at the DIY sheds. I'd be very interested to hear what the 'Premium' manufacturers, such as Stonemarket, have to say. I know that applying a quality sealant 6-12 weeks after laying will certainly extend the life of their products, but that's just bumping up the cost even further, and not everyone is keen on the finish that comes with the sealants. In your case, I think you should take a good hard look at what's on the market. There's a good few natural stone suppliers in and around Preston, so have a shop around, see what sort of prices they''re asking, and weigh up whether you're better off sticking with the devil you know or switching to a natural stone product. |

|||||

|

|

|||||

|

Unhappy with Contractor - Toomuchcoffee - 5 Dec 2002 | ||||

|

Hi Tony,

Just some background first: We have recently had our backyard paved with Stonemarket indian flags. The total area is about 95sqm. There is a patio section in a dark limestone color, which comes out from the house about 4m, then a lighter color is layed directly adjacent running out to the fence and to the side of the house. In the middle of the light colored area an admiral star pattern has been layed, which is circular but we purchase a squaring off kit for it which makes the shape square. A professional marshall accredited landscaper was engaged to do all the works, which came to a total labour cost of about 3500 pounds. The first piece of work performed was the patio area, which was layed almost to perfection. All gaps were in the range of 10-15mm, all stones were laid straight, and we were very happy with the work. Next the admiral star pattern was layed. We queried the contractor about doing this before the surrounding stone was layed, and he assured us he knew what he was doing, so we let him go. We did also ask him whether he needed to measure and distances before laying this pattern (my wife indicated where we roughly wanted it, but we thought he would need to measure things so that it could be laid square), but he again assured us that he knew what he was doing so we shut up. The pattern was laid and it looked great. The next section layed was a 1m wide strip running away from the patio flush against the left hand fence. The flag sizes were a mixture of 1x1, 2x2 and 1x2. At the landscapers request we were not present on site during the day at all, so we arrived home in the evening do discover:

- gaps in the stone ranging from 10mm to 60mm

I spoke to the landscaper that same evening and asked if he still had more to do before completing that work (I could not believe it was complete because it looked so different to the first piece of work he had done). He replied calmly that yes it was, and he was going to continue in the same fashion for the rest of the yard. I explained that we were very unhappy with the workmanship, and he asked if we wanted him to rip it up and do it again - I replied yes. He initially said we would have to pay extra, but I stood my ground and he relented. During this conversation I repeated several times that I did not want to see any gaps exceeding 20mm, but to aim for 10-15mm as the norm, and he agreed. I also raised the issue with him that having measured distances between the house, fence and edges of the admiral star pattern, that there was a 1:30 run out of square on the edges. I asked if he would be able to lay in a way that this could not be noticed and he assured me he could. Well, the next day I went through these details again with this co-worker (who generally arrived long before he did), and made it clear about what we wanted (the same standard as the patio). When we arrived home that night we were pleasantly surprised to see much better workmanship, although some of the gaps were 30-35mm. I was prepared to let one or two go, however the next morning I re-iterated that if any further stones were laid with such a big gap we would reject the work. He had not done anthing about the star pattern at this point, and the run he had laid was still about 1.5 feet away from the edges. The next day he layed some more stone near the patio, and adjacent to the star pattern. He had cut some stones at angles to make them fit. When we saw this, it was very noticable that the star was out of square, and we reluctantly asked him to please re-lay it square (since that's what he should have done to start with). He was not very happy about it, but he agreed to. The star was re-laid that day and it looked much better. He then proceed with the next piece of work. Again he had laid some stone with large (30-40mm) gaps. When we saw him the next day we asked him to re-lay those, and not to exceed 10-15mm. He then said he didn't realise that we felt so strongly about big gaps, but he would be careful in future (I don't know how I could have communicated it any more strongly without shouting it at him The next section was laid very nicely - no complaints. The next section - nearing the end - guess what? - In one section he had 30-35mm gaps, then as he approached the wall he had to cut stone to fit - I just could not understand how he could ignore such simple requests. Both my wife and I were starting to feel weary with the whole process at this stage though (5 weeks since beginning, my wife having to leave home each day and loiter elsewhere while he worked), and we decided to let it pass, and hope that when it was pointed it would not be too noticable. The final section laid was a small path to our rear gate (1mx3m), and the work was not great, but it was acceptable (20-25mm) gaps, not all stones square - this was using the smaller stones. Some of the stone was left several weeks unpointed at this stage. and the first 5 weeks of weather (aug, sept) was fantastic. The only stone that had been pointed at this stage was the patio area, which was a wet-mix and had only been done because we had badgered him so we could use the area. Finally he came with some extra workers and did all the pointing in 2 days using a dry mix. He claims to use extra concrete in his mix to make it work better. The rain had begun now and he had to point on dry days (2 days 3 days apart). We gave the point 3 days before using the area, and our usage is only light pedestrian traffic. But we noticed that some of the stones were loose - some with a small hard to notice wobble, some a very bad wobble. The pointing also had not seemed to set properly, and was flaking, and falling apart - some areas worse than others. We called the landscaper back and asked him to correct it. He came and inspected the problem, then came back to me with the following statements:

1. He agreed the work was faulty and needed fixing.

The next day he contacted me and agreed that he would do the work ASAP without first receiving the final payment, but all other conditions held. He then said that he would be coming around that afternoon to barricade the yard off from the patio so that our children could not disturb the work whilst he was working. After barricading the area he would 'make contact' with me and plan the next step. I replied that I was very unhappy with setting up a barricade until we agreed when the work was going to be done, because I was concerned that it might be weeks or months before the work was done. He said he couldn't give me an estimate of when he could do the work because he was too busy to work it out. I asked him to work it out and get back to me. That was a month ago and I have not heard from him yet. sigh. Now to my questions:

1. given the current weather conditions, is it unreasonable to expect him to do the work successfully until the weather clears?

We really want an amicable solution, but at the moment we feel that we have paid a small fortune (8500 in total) for a job to be done well, and it has been almost ruined by his current workmanship. We really need some professional advice about what is fair in terms of our own expectations, so that we can approach him with confidence. For example is it fair to be fitted around other jobs he is currently doing when he still hasn't finished ours? As a last resort I guess we could get someone else to come and fix the job, but the way I see it, that would open up a pandora's box of legal issues, who would honour guarantees etc. Your advice in this area would be greatly appreciated.

Thanks |

|||||

|

|

Tony McCormack - 6 Dec 2002 | ||||

|

Well, that's a comprehensive report...I'll take your questions one at a time....

1. given the current weather conditions, is it unreasonable to expect him to do the work successfully until the weather clears?

Yes - but I get the feeling he won't return when the good weather does. 2. Should we be expecting this to not happen until spring? If we got a reasonable spell, then there's no reason why it couldn't be done anytime. The two killers are Frost and Rain, but if we experience a couple or three days of dry weather with temps no lower than 4C, then that would be OK. 3. Since the rain has increased, we have now noticed a large puddle forming. Then the paving should be relaid to the correct falls. 4. How much work is likely to be involved to fix the puddle? Without seeing the job, I can't really say, but it could be perhaps half a day. 5. How much work is likely to be involved to fix the pointing. It all needs re-doing, from the sound of it. A good tradesman and labourer should be able to point around 100-150m² per day. 6. How much work is involved to fix each wobbly stone. It's often easier and quicker to take up and relay a larger area rather than fart around lifting and relaying individual flags, but estimate 10 mins per flag, maximum. 7. What is reasonable for us to expect from him in terms of quality (he is a marshals gold-member) A damn sight more than you've experienced to date. If this contractor is giving you the runaround, and from what you say, it would seem he is, then get Marshalls in to resolve the matter. That's what they get paid for with these 'Approved Contractor' schemes. All the companies that organise these Approved Contractor scams, oops, I mean "schemes", are happy enough trumpeting their value to householders and the "peace of mind" that allegedly comes with insurance-backed guarantees of quality, but there remains a disturbing gap between their laudable aspirations and the actuality. Marshalls are a reputable company (and they don't pay me to say that!) and if you've been 'done' by one of their members, I'm sure they'd want to find a resolution. Have you put all this in writing to them? Have you had any response? Let us know how you get on. |

|||||

|

|

|||||

|

Re-laying a patio - Manic1 - 17 Dec 2002 | ||||

|

Exactly 4 years ago, a brickie "friend of a friend" layed me a patio of about 3 X 10m, on heavy clay, in wettish conditions. He dug out and compacted about 60mm of hardcore and then blinded with 35mm of sharp sand, before laying the 40mm x 600mm x 600mm flags on mortar spots, without using a line or spirit level! Suffice to say that within a year, all the pointing was breaking up, about 30% of thee flags were rocking, and the patio resembled a cross between a graveyard and an earthquake zone ! I ended up relaying all the "rockers", and re-pointing the lot. I can only presume that the combination of wet weather and spot laying resulted in the rocking flags, but i'm not sure why the pointing fell out.

Anyway, i'm shortly having a conservatory built, which will reduce the patio to about 3 x 5.5m, so i thought i might re-lay the patio myself, with random, riven buff flags.

Here's the plan!

Apologies for all the questions, but i want to do the job properly, and once only !

Finally, may i congratulate you on just about the most informative, relevant, and professional website i have visited for a long time. You are a credit to your trade. Mark. |

|||||

|

|

Tony McCormack - 17 Dec 2002 | ||||

|

Brickies! Pah! Will dry pointing be suitable? Yes, if done on a dry day. Don't expect it to last for ever, though. You get a better lifespan is you have buttered joints that are dry-pointed within an hour of laying.Working time with 10:1 semi-dry bedding? Around 4 hours. After that, you can reinvigorate it by adding a spadeful or three of fresh cement.Screeding? Yes - screed across the shortest dimension, remembering to allow 6mm or so for compaction. With less than 5m² to lay, you should be able top cover the ground before lunch time.Point as I go? You can do, but with such a small area, you could leave it until you've all the full flags laid, then go over it again when you've done any cutting-in.Is dry pointing waterproof? Not 100% but it will be satisfactory for what you want. Like the sand jointing used with block paving, dry-pointed joints develop a crust of crud that forms a pretty damned effective flexible waterproof seal after a few weeks.If you want 100% waterproofing from day 1, then consider wet-grouting. Good luck - let us know how you get on. |

|||||

|

Manic1 17 Dec 2002 |

Tony,

Thanks for the info, i forgot to ask...... 1) Are flags laid on a COMPLETELY dry 10:1 bedding mix 2) As i have nearly 16metres sq. to lay, not 5m sq. surely i must dry point as i go, as i'll never finish laying that lot in 2 days, let alone ½ a day!!! 3) As it will be difficult to remove all the existing blinding/bedding sand, would it be a good idea just to scatter some cement and rake that in before compacting it, and then laying my 40mm 10:1 bedding? 4) Do i actually compact the 40mm 10:1 bedding layer and then add 5 - 8mm loose for compaction by the flag, or do i compact enough 10:1 to finish up 40mm thick after the vibrator plate, and then add the 5 - 8mm flag compaction layer? 5) If i decide to "wet point", is it better to point to a flush level, or a few mm lower than the flag surface, as i've seen both methods with the riven flags i intend to use, but the flush pointing on my current crappy patio is all cracked and hasn't adhered totally to the flag, as if it has either shrunk, or frost/water has got under the edge of the flush pointing?

Thanks again for your help already,

|

||||

|

Tony McCormack 18 Dec 2002 |

Taking your points one at a time...

1 - it's not completely dry: it relies on the inherent moisture of the sand, so we call it a semi-dry mix. There is no water added during the mixing process.

2 - 16m² is still only 80-odd 450x450 flags, so if you can lay 10 an hour, you'll do it in a day. Dry point as you go, if you prefer. It won't do any harm.

3 - I'm not sure I follow. It's best to clear the entire site before starting to lay. You need to in order to get the plate compactor in to consolidate the sub-base.You can put out the bedding as you need it, stirring/raking cement into the sand as you require, if that's how you prefer to work. 4 - lay 50-60mm of bedding; compact lightly, screed off to 6mm or so high, and then lay flags. Only trial and error will determine exactly how high to levae the screed to allow for consolidation, but, with a 40mm bed, 6-8mm will be about right. 5 - point to slightly below the surface. Bucket handle pointing is best; that's the rounded, concave finish that's easiest achieved with a pointing bar or a short length of copper pipe. |

||||

|

|

|||||

|

Raised patio - Paul Williams - 1 Jul 2002 | ||||

|

Hi Tony, superb site and so much information.

I am building a raised patio which extends 4m out from the house, is 7m wide and 1m high. The very gravelly soil I have excavated for the footings will allow me to infill up to a height of about 300mm. I was going to use crushed concrete to make up the remainder. Will this provide a stable enough sub base, and at what heights do you suggest I compact it before adding another layer? |

|||||

|

|

Tony McCormack - 2 Jul 2002 | ||||

|

Should be fine, Paul. Compact in 150mm layers before adding next lift.

What are you using as a retainer? Walling? Have you considered drainage? |

|||||

|

Paul Williams 4 Jul 2002 |

Thanks for the advice Tony. I was going to use a brick retaining wall and a perforated drain as per your diagram. | ||||

|

Tony McCormack 5 Jul 2002 |

Sounds fine - as long as you have somewhere to outfall the drainage pipe. | ||||

|

Paul Williams 27 Aug 2002 |

Yes, I have land drains already there and was going to tap into them.

Can you clarify one thing? The raised patio effectively has four retaining walls; the back of the house, 2 extending out from it and another paralell to the house.

|

||||

|

Tony McCormack 27 Aug 2002 |

No - just the one at the lowest point. Assuming fall is perpendicularly (is that a word?? ) away from the house, then you need a land drain at the wall at the far end of the patio, and none on the 'side walls'. | ||||

|

|

|||||

|

Which way is up? - Angela Beacham - Sep 5th 2003 | ||||

| We are just about to lay some chamferred edge natural stone paving slabs and are being given conflicting advice, narrower edge (the rougher side) up or down? | |||||

|

|

Tony McCormack - Sep 8th 2003 | ||||

|

If I understand you correctly, then it should be "chamfered" side down.

In this picture of an Indian sandstone flag, taken 'edge on'....

....you can see that the edge tapers in - this is known as a 'fettled edge'. The base of the flag has a slightly smaller surface area that the top face, and, you should be able to identify that the top face edge has a definite straight edge, whereas the base is somewhat more haphazard.....

...does that make it clearer? |

|||||

|

|

|||||

|

Sealing Flags Indoors - Andrew Williams - Sep 10th 2003 | ||||

|

I have just laid a couple of flagstones as a hearth with a wood burner to go above. The flagstones are new cut and around 2 months old, the area is around 2 sq metres with 1 join straight down the centre and exposed at the front to the living room. Can anyone recommend an appropriate sealant to protect against the heat and soot and how long should I wait before I treating the stones.

Many thanks - Andy |

|||||

|

|

Tony McCormack - Sep 11th 2003 | ||||

|

I think you're better off with a wax-based 'polish' for internal usage. Golvpolish seems to be the most popular, but I'm not sure how (or if) it copes with heat.

Hagesan's products (including Golvpolish) are distributed by Topp's Tiles, so, if you comtact your local branch, they should be able to advise you on what would be most suitable. |

|||||

|

|

|||||

|

Paving around swimming pool - Brier - Sep 4th 2003 | ||||

|

We want to lay about 70m² of paving around a swimming pool that will be constructed during the coming winter. A contractor we contacted has suggested a 10cm reinforced concrete base for the paving over a sub-base of crushed limestone. This seems OTT to us given the relatively light useage the paving will receive. I should say that our land is about 1 inch of soil over limestone!

Do you have any recommendations for laying paving around pools? Thanks in advance |

|||||

|

|

Tony McCormack - Sep 5th 2003 | ||||

|

Given the amount of disruption that takes place during construction of a swimming pool, and the subsequent backfilling, I'd say that your contractor is probably right.

It doesn't matter what the ground is like now - once the pool is built, it will be what we calll 'made ground', that is, it has been excavated and backfilled. So, if you want the paving to stay put, best use a concrete base. |

|||||

|

|

|||||

|

Manhole Covers - Gary Homer - Jan 21st 2003 | ||||

| I am contemplating having a go at relaying the patio, in riven paving, I want to do the random pattern shown in the Stonemarket brochure, but I have one small problem, right in the middle of the patio is a circular manhole cover 14 iches diameter, flush with the current slabs. How do I get over this problem, is there a carrier available to put the slabs in to, and could a reasonably skilled amateur undertake this task? | |||||

|

|

Tony McCormack - Jun 21st 2003 | ||||

|

You've two options, Gary. You either cut the flags to fit around the existing circular IC cover or you replace the cover with a recess tray cover, as shown on the Recess Tray page. If you elect to cut around the existing cover, you may need to adjust its level - the cover should be made to fit the paving, NOT the paving fit the cover. This is usually pretty easy for small adjustments, but owt more than 25mm up or down requires a bit more skill. Also, cutting the flags neatly in a circle isn't the easiest task, but I can talk you through it, if needs be. A recess tray cover is a better option. It'll cost you maybe 40-50 quid for a decent 450x600mm cover and frame, but the beauty is that it's damn near invisible once installed and won't spoil the overall look of your patio. It's a Universal Law that, no matter how much you spend on paving, if you leave an IC cover in place, that's all your eye will see.

And it's much simpler cutting the flags in straight lines to fit the recess tray than trying to cut a concave curve. |

|||||

|

|

|||||

|

Kerridge stone - Meccano man - Jan 30th 2003 | ||||

| Before we go and buy 3 tons of Kerridge Stone crazy paving flags, has anyone any advice on this type of stone? | |||||

|

|

Tony McCormack - Jan 30th 2003 | ||||

|

What are you planning to do with the Kerridge stone? There's been a few problems with it on at least one job I know of, because of excessive mica causing delamination (it's flaking and falling apart, in layman's terms).

Is this new or reclaimed Kerridge? |

|||||

|

ALS Jan 30th 2003 |

Where can I get info on this crazy paving flag stone | ||||

|

Tony McCormack Jan 30th 2003 |

This particular stone (ie: Kerridge) or stone for crazy paving in general?

Kerridge stone comes from a couple of quarries on the outskirts of Macclesfield and has been used for paving for over 500 years. Some of the original Kerridge stone is used in a dead famous cathedral somewhere down south - Winchester, p'raps, maybe Wells - I can't recall. However, all natural stone varies through its quarry, and some of the 2001 Kerridge stone I've seen on a job in South Manchester is, literally, falling apart. It's not solely the fault of the stone; it's been badly laid, and some of it is ok, but it's not up to the job on this particular project. For stone crazy paving it's usual to use a 'random rubble' paving stone, which means it is NOT trimmed into squares/rectangles, but is haphazard shapes. There's a page on the website dealing with the dubious joys of crazy paving - have you read that? |

||||

|

Meccano man Jan 30th 2003 |

The stone is new from one of the quarries.

All the stuff I've looked at appears good quality. I can understand how that delamination could occur, because of the variable thicknesses of some the layers. The stonemason we're working with has never used this type before, but looking at the sample we've got, he reckons that with a decent bed (at least 30mm) we will remove potential problems. We also are looking to use two part epoxy to bond the stone to a set of brick / wood steps, any known problems with this technique?

The main reason for choosing the crazy paving, rather than Yorkstone / Indian sandstone regular flags is that the path is basically an elongated 'S' shape, and will require large amounts of cutting to shape and the steps mentioned above will need a load of detail work for the flags. The decision came down to cost:

Given the shape and design, we will have to throw about 30% of the regular stuff away! Hence the choice of crazy paving. |

||||

|

Tony McCormack Jan 31st 2003 |

Which quarry? Use the Messenger facility above, or email me, if you don't want to say in public. Not all of the Kerridge producers are members of the Stone Federation - make sure you get a written specification from the quarry that states the stone is suitable for the project.

The delamination we've witnessed occurs because of excessive amounts of mica. Water gets to the mica, causing it to expand, which, in turn, prises open the laminae of the stone. I'm not sure an epoxy is the best way to bond this stone, or any riven-type stone, to the risers of steps. There is a lot of variation in unit thickness with a riven stone and epoxy isn't as good as mortar for taking up the differenmce between mis-sized adjacent units. If strength of bond is an issue, then I'd use a SBR-enhanced mortar rather than epoxy. It's also highly likely that the epoxy:stone bond will be significantly stronger than the inter-laminae bonding of this type of stone, so, if there is any 'movement' it will result in the flagstone being ripped apart, rather than it coming loose from the bedding. Here's a couple of pix....

The photo above shows the delamination adjacent to a 10p coin for scale, while the picture below shows the delamination viewed 'edge on' where it's been used for a poorly constructed step.

Note the abundance of mica (the sparkly, shiny particles on the surface) in the top photo. Is your stone like this? |

||||

|

ALS Jan 31st 2003 |

It was the Kerridge stone Tony, thx for the answer | ||||

|

Tony McCormack Jan 31st 2003 |

I don't think Kerridge travels as far north as you, but if you have a specific project in mind, I can put you in touch with the two major quarries. | ||||

|

ALS Feb 3rd 2003 |

Could you give me a hyperlink or e-mail address for any quarries in Scotland Tony? Cheers Als |

||||

|

Tony McCormack Feb 3rd 2003 |

There's a few different types of stone used for paving in Scotland. Granite and Whinstone are popular, but you can get sandstones. I've just checked the Stone Suppliers Links page, and there's only one Scottish Quarry listed, which means I'll have to update that a.s.a.p., but follow the links to the Stone Federation site or Stone-Mart and that will link you to more suppliers in your particular area.

You can get the imported Indian sandstone in Scotland, if price is more important than authenticity. |

||||

|

|

|||||

|

Flags on crazy paving - Alec - Feb 1st 2003 | ||||

| How can I lay concrete flags on natural stone crazy paving? | |||||

|

|

Tony McCormack - Feb 2nd 2003 | ||||

|

Can you give us a bit more info? Do you want to lay concrete flags on top of an existing crazy-paved surface?

Have you read the page on Damp Proof Courses? Will you have sufficient room to accommodate the concrete flags plus the requisite bedding? |

|||||

|

Alec Feb 2nd 2003 |

Yes I want to lay Concrete flags on top of existing natural stone crazy paving. If the existing crazy paving is stable enough could I lay on a bed of mortar? I realise I need to check the height of the DPC. | ||||

|

Tony McCormack Feb 3rd 2003 |

You've got the basic idea right, but I recommend a semi-dry mix, rather than a wet mortar. It gives you more working time, it's cleaner to work with, and it's less likely to cause the flags to 'float' during the laying process. 8:1 or 10:1 grit sand to cement should be strong enough.

Don't forget to allow for drainage, and to point the joints with a Class II mortar, as described on the Pointing page. |

||||

|

|

|||||

|

Coloured Pointing - Gary Homer - Feb 2nd 2003 | ||||

|

When you look at the many paving catalogues provided by the manufacturers, they all show the buff or york coloured flags, having been pointed in a mortar the same colour as the slab.

How do you achieve this, is there a colour additive available, and if so, where from? |

|||||

|

|

Tony McCormack - Feb 2nd 2003 | ||||

|

You can get mortar dyes from most Builders' Merchants, Gary, and they come in a wide-ish range of colours. Reds, Buffs, Browns and Blacks are the most common, but there are in-betweeny shades, such as 'Marigold' (a sort of pale orange) and 'Tan' (a sort of reddy-brown). Blues and Greens are much more expensive and really not worth the effort for paving pointing.

Most of the dyes are based on metallic oxides and they work by colouring the cement in the mortar/concrete. The amount of dye used varies from brand to brand, but 1kg dye per 25kg of cement is a typical mix for a reasonably coloured mix. However, most, if not all, dyes fade over time, and what starts out as, say, dark brown will mellow to a mid-brown over a couple of years. You can mix the dyes to develop a shade you find attractive. You could, for example, mix buff with brown to get a honey sort of colour. You should also know that the colour of a freshly mixed 'plastic' mortar can be hell of a lot different from the same mortar a week later, when it's cured. |

|||||

|

|

|||||

|

Selling York Stone Flags - Sharon Cole - Feb 3rd 2003 | ||||

| I am looking for information on how to go about selling old york stone flags. Would like to know how much they sell for. I have recently had about 20 stolen you see and would now like to sell the ones which have been left. They are about an inch and a half to two inches thick. | |||||

|

|

Tony McCormack - Feb 3rd 2003 | ||||

|

Hi Sharon,

The value of yorkstone flags depends on two things - their surface characteristics and their thickness. Good quality, worn or lightly-riven flags are the most prized, and the 30-50mm thick stuff is the mutt's nuts. However, before you start planning a round-the-world trip, you shouldn't expect too much. Up here in t'north, you might get 10-15 quid per square metre for them, whereas if you went to buy replacements, you'd be charged 35-45 quid for the very same flags. In the South-east, you might get 15-20 quid, but some dealers will pay less if they have to send a gang of donkeys around to lift and shift. And if the surface is heavily riven, if corners are missing, if there's any delamination or if they are 75mm+ 'ballbreakers', then you'll get considerably less. Phone round a few dealers first to see what price they'll quote you, then invite 2 or 3 around to make a firm offer, but be wary of mobile numbers - flags have been known to 'walk' overnight, once their location is revealed. Try and agree a price AND get them up and away on the same day. Good luck! |

|||||

|

|

|||||

|

Fixing poorly laid yorkstone - Jeff Douglas - Feb 4th 2003 | ||||

|

I have been asked to comment on problems with a large domestic patio laid in early 2001 in Yorkstone flags.

The owner obtained the flags from Dolmens in West Yorkshire (about 200 sq. m) and asked a contractor to lay them. Some problems have occurred since which the owner has asked me to look at. Firstly, some of the pointing is breaking up and can be easily rubbed up with the heel of a boot. It looks like a sand grit mix but with a varied and lean cement content. Secondly, some of the slabs are rocking although this is relatively few in relation to the area. After lifting several of the flags, they are very irregular on the underside and have been laid on spot bedding. However, the contractor did lay a 100 thick concrete sub base underneath. The owner thinks that all the paving needs to be completely relaid due to the spot bedding but as it is on a concrete sub base, I'm not sure if this is overkill, particularly as it's such a large area involved. Also, as the joint widths are very irregular and very wide in places, what sort of pointing method is best? Your comments would be very much appreciated. |

|||||

|

|

Tony McCormack - Feb 4th 2003 | ||||

|

Hi Jeff,

the pointing can be tested in a lab to determine cement content, but, if it's falling apart to the touch, then you don't need a lab to tell you it's crap. More worrying is the dreaded spot bedding. I've argued with architects, designers, paving manufacturers and even a few site agents about this, but, with almost 50 years experience as a paving company, we never, ever, ever recommend or install using spot bedding. It's a recipe for disaster. With a concrete sub-base being present, the best option is a 'lift and relay' on a full bed of cement-bound material (10:1 gritsand/cement), but if that isn't feasible, then a wet-grout might resolve the rocking and the pointing issues in one fell swoop. Joint width should not exceed 20mm as an absolute maximum. 10-15mm is ideal. If folk are paying umpteen quid per square metre for yorkstone paving, then they shouldn't be confronted with 10% naff mortar joints. The joints should be regular and kept to a minimum. |

|||||

|

Jeff Douglas Feb 4th 2003 |

Are you suggesting that the whole area of paving should be lifted, even where it's still firm after two winters, or should this be just to those flags that are rocking? | ||||

|

Tony McCormack Feb 4th 2003 |

It's up to the client and yourself. I haven't inspected the job, so I can't say, for certain, just what is best, but I'd certainly consider wet-grouting the loose areas to see if that rectifies the situation before considering summat more drastic, such as a lift and relay. | ||||

|

|

|||||

|

Crazy Paving Problems - Anji - Feb 16th 2003 | ||||

|

I'd like some advice on our crazy paving which was laid at the end of our building work by our builder's men (not a specialist drive company) in June/July last year; it took them 4 weeks to complete the job. Afterwards there seemed to be a lot of sand that needed to be brushed away. I put this down to excess building material lying on the surface. However, 6 months on and there is still plenty of sand to deal with, all seeming to be coming from the pointing. If I rub the pointing with my foot it scratches off and in some areas the pointing has broken away (areas where the builders scraped away the pointing and redid it after heavy rain damaged the original) and has left little gullys between the slabs. Some of the pointing stays wet- looking, with a distinct sandy colour, long after all the puddles have dried up.

There is approx 30m² of paving for the drive and 30m² patio plus paths. How long might the drive/patio last do you think or does it need repointing urgently? Having lost faith in the builder and his workmanship (for more reasons than the paving) I am reluctant to get him back to do any repairs and wonder if I could tackle it myself section by section or do I need to get in someome who knows what they are doing? One other thing – I read your section on DPCs. At the rear of the house, the builder has put in a step adjoing two sets of french doors. It abuts 4 metres of wall and starts 10cm below the DPC and finishes 5cm above it. There is some blue plastic membrane peeking up from behind the brick edging (what do I do about that? – very unattractive) but no dry gully has been constructed as you describe in your section on DPCs. Is this likely to cause long term problems? Your web site is really excellent; great information, well set out – just the sort of thing we want to find on the web but rarely do. Thank you. - Anji |

|||||

|

|

Liam Booth - Feb 16th 2003 | ||||

|

It sounds like the pointing wasn't made up in the right parts, ie sand cement. When the cement becomes crumbly and starting to eventually wear away, it is an obvious sign that it hasn't been made right.

Anyway, what made you choose crazy paving, it is the ugliest, out of date style to use. If the builder had been any good he would have told you how out of fashion it is, nowadays. I would seriously consider calling him back. I hope this helps and Good Luck!! |

|||||

|

Tony McCormack Feb 16th 2003 |

I agree with what Liam says - Crazy Paving is a desperate choice and actually takes far more skill to lay correctly than does block paving or even standard flagging!

The mortar pointing is far too weak, that's why it's 'dusting', and it will never get any better. The only option is to cut it out and re-point.... BUT ...who do you get to do this? I think it's grossly unfair to expect you to do it. Believe me, you will hate the task within half a day. It is boring, laborious, back-breaking work, hunched over for hours upon end making little progress. When I was working, it was the job assigned to whichever apprentice had most annoyed me over the preceding fortnight.

So, you should call back the builder, but will they come back? They've been paid; they're on with other jobs now, jobs that are paying a wage, and they'll not be keen on coming back to redo a job in which they are not proficient and will not be earning. It's odds-on that they'll send down their 'odd jobber', with the instruction to do the bare minimum, with as few materials as possible, in as little time as possible. It's almost guaranteed to end in tears. You're legally (and, some would say morally) obligated to ask back the original contractor. If they can't or won't play fair, then you can seek another contractor and employ them to undertake the work, and then use the <spit> lawyers to force the original contractor to cover your costs. That could, and probably would, take years to resolve and the only party guaranteed a happy outcome is the <spit> lawyer. I would put your concerns in writing and send them to the original contractor, asking for a response and their proposed remedial plan within 14 days. It might elicit a response, but you have to be prepared to bring in your own contractor. If the original firm do offer a 'fix' then you need to have an agreement in writing as to the expected standard of work, the materials to be used (ie, strength of mortar) and a timescale. In fact, even if you end up using a new contractor, these things should be agreed in advance. Now, what else was there...oh yeah - the dpc. The blue placky membrane can be trimmed with a craft knife. The construction you describe is less than satisfactory, but without seeing the steps for myself, or seeing the original design, I can't say just how good or bad it is, or whether it poses a long-term threat to the rest of your property. Do you have any photos? |

||||

|

Anji Feb 23rd 2003 |

Thanks for your comments/advice - it is as I feared. As I do not feel vengeful enough (or rich enough) to involve lawyers and hope never to set eyes on Bob the builder ever again, I guess we will have to put this down to experience and patch up the bad bits to try and eke out the paving until we can afford to get it redone properly - maybe changing the surface eventually.

I have put a couple of photos of the steps on:

As for crazy paving - call me old fashioned, but I rather like it (when done properly, of course). We have a 1930s house, white painted roughcast house, green roof tiles and not a bare brick(*) in sight; Brick block paving, preferred by Bob the builder, really wouldn't suit. I walked the local area looking at different surfaces and was happy with crazy paving as an alternative to brick. We did suggest some other options but when he started working out how much extra to charge us we stuck with the "cheaper" option. (Labour costs didn't seem to bother him as the men were on his books anway and they seemed to tackle our paving as a fill in job during gaps in their other contracts). * Lots of brick now as Bob's blokes edged the paving with brindle brick - still not sure if it clashes or not. |

||||

|

Tony McCormack Feb 23rd 2003 |

I agree that crazy paving can look good, when laid properly, but so much of it isn't laid properly, which makes it so problematic.

I like the basic idea behind your steps, but I'd make the following comments.... 1 - there's a lot of mortar. Those wide joints are already causing problems because of the weak mortar; as they darken and get colonised with vegetation over the next 12 months or so, they'll begin to look untidy. I'd get them re-pointed, even if you do it yourselves, a bit at a time, using a strengthened mortar. 2 - brick edging. I can't quite tell from your piccies, but aren't the spacer lugs on the blocks visible? A clay paver or engineering brick would have looked better and given a more professional finish.

The overall design looks right for the property; it's just the implementation that's let you down. |

||||

|

Anji Feb 24th 2003 |

I've just had a look - yes indeed - the spacer lugs are visible - wondered why the edges of the steps looked odd. What a shambles!

Thanks for your advice. I'm just off to bang my head against a brick wall - if it's one of Bob the builder's it's likely to crumble away rather than hurt..... |

||||

|

|

|||||

|

Greenhouse Base and Paths - Max Ali - Feb 18th 2003 | ||||

|

I've just brought a 8.5' x 10.5' aluminuim green powder coated greenhouse made by Robinsons. Although it can be placed directly onto my grass lawn I thought it would be better to put bolt it on to a concrete plinth. What size do you think the plinth should be and what mix of concrete/sand/gravel should I use?

I would also like a mowing edge around the greenhouse. Once again what do you think would look best. I don't want it more than 12" wide. In terms of the inside of the greenhouse what kind of a finish do you think would look nice? I'm not keen on plain grey slabs. I want something that is traditional and will look good against the dark green finish of the greenhouse. The greenhouse should last more than 30 years so all materials will ideally need to last as long. I have a Travis Perkins near me so if you recommend anything they stock I will be able to view it quite easily. Thanks very much for your help. Max |

|||||

|

|

Tony McCormack - Feb 19th 2003 | ||||

|

Hi again Max,

good to see you back in the Brew Cabin, and what a good choice of Greenhouse - I wish I had the room for something a bit bigger than my little ally 6x8, as it's bursting at the seams, thanks to my love affair with fuchsias! For the base, you could either go for a solid slab that is roughly 300mm larger than the GH, giving 150mm of 'spread' on each edge, or you could go for the 'strip footing', which is a concrete-filled trench. The latter gives you direct access to the soil, but many modern gardeners, myself included, like to have a solid concrete floor and then rely on gro-bags or pots etc, rather than the underlying soil. The concrete should be at least a C20 equivalent, as described on the Concretes page, and you can knock this up yourself, or buy-in as Ready Mix. Whether you go for the 'raft' or the strip footing, the concrete only needs to be 100mm thick, as it's not taking any vehicles. For the Mowing strip, I quite like using the larger tumbled pavers, such as Tegula/Drivesett by Marshalls, Woburn from Charcon, or Alpha from Brett. The Tegula/Drivesett are 240x160x50/60 and, laid 240 wide, they make a great mowing strip, and look quite naturalistic in the garden. They cost around 18 quid per square metre, which, when laid as a single course, 240mm wide, works out at around 4.50 per linear metre. Inside the GH, I like to use plain concrete flags. They're not 'on show' as it were, so anything will do, from reclaimed 2x2s scrounged from a local driveway redo, or even the budget stuff from the DIY sheds. In my GH, I have a solid concrete floor (a raft), on which is built a low wall, just 4 courses high (300mm) topped with a wooden batten and the GH itself is fastened to that. This arrangement gives me extra height in the GH. The central path is made from 600x600x40mm Marshalls Heritage riven flags, laid on a cement-bound bed, so that they are, roughly, 100mm higher than the concrete floor.

Your first decision, though, is whether to go for a raft or a strip footing. You decide and I'll do the calculations for you. |

|||||

|

Max Ali Feb 19th 2003 |

Thanks very much for your comprehensive reply. I'm in that difficult position in that I've had to spend a lot of money on the greenhouse but don't know if I can justify spending a load more getting it up (so to speak).

I had a look in a few gardening books and I have to admit that my favourite was the use of a small basketweave path around the edge of the greenhouse and also as a central path in the greenhouse. Either side of this in the greenhouse I would have gravel on top of a weed suppressent membrane. I'm not sure what type of blocks would look best against a green coloured greenhouse with lawn around it. I was thinking about using a concrete plinth/strip footing to put the greenhouse on. Do I need to put in a sub-base for either the greenhouse or any of the paving I lay? Also is there any similar need for a sub-base below the gravel. I will have a look at my Marshalls catelogue tonight to see the pavers you have mentioned. They certainly sound nice. Thanks very much for your help. Max |

||||

|

Tony McCormack Feb 19th 2003 |

If you fancy a basketweave path, go for it. The narrowest feasible basketweave would be 400mm wide, assuming you use 200x100mm block pavers, which is fine for a mowing strip, but I'd definitely go for 600mm wide down the middle of the GH itself. 400mm is awkward for standing on - you can't escape the feeling that you're about to 'fall off' at any moment.

Just about any blocks would go with a Green GH, but, in garden settings, I prefer the more natural colours. In the Marshalls range, the Burnt Ochre (a multi-brown) is, to my eyes, more garden-friendly than a multi-red brindle or a loud yellow (buff). Have a look at the Burnt Ochres (Brown Multis) on the Portfolio page - that's a job we did some years ago in Rochdale. For the paths you're proposing, I wouldn't bother with a traditional construction - I'd bed everything on 75-100mm of lean-mix concrete, say a 8:1 mix (C7.5 equivalent). Even with a 600mm wide path, by the time you bedded the outside edges on concrete to hold everything in place, there's only a 400mm gap left to fill, which is hardly worth the effort of placing sub-base and then a sand bedding layer. I'll post a drawing to this thread later.

For the strip footing: dig a trench roughly 100-150mm deep and 300-450mm wide, and fill it with C20 equivalent concrete. Tamp to level, and it will be ideal for carrying your GH - I'll add a drawing of that, too, but only after I've watched Countdown and had me tea! |

||||

|

Max Ali Feb 19th 2003 |

Thanks in advance for your help. I was going to put a 1 metre path in the greenhouse for the reasons you mentioned and use lengths of timber to stop the edges wandering.

Would I not get away with a mowing edge around the greenhouse with a width the same length as a paver(200mm)? |

||||

|

|

|

|

Tony McCormack Feb 19th 2003 |

If you go for a basketweave path laid on a sand/cement bed (C7.5 concrete equivalent), that will preclude the need for any timber edges - you can use the bedding to haunch the edges, as shown in the drawing.

Going back to the mowing strip, 200mm means you can't do a proper basketweave, but you can do a sort of half-basketweave, I s'pose....

|

|

|

|

|

|

|

|

|

Max Ali Mar 3rd 2003 |

I've had a chance to go down to my local TP and look at the blocks/setts. I've also got the Marshalls 2003 catalogue. I've narrowed my selection for the basketweave mowing strip and greenhouse path to the following:

Chapelgate brick pavers in Red Multi (page 53 in the catalogue);

I would like to point between the pavers so that I get that "olde cottage look" to the finish. However, I noticed that the catalogue says the Old Mill Bricks are "...primarily intended as a walling material. When used as a decorative paving feature, it must be noted that the surface will abrade under foot traffic". Do you think this will affect me to any great extent since only the path in the greenhouse will be affected by foot traffic and even this will be limited to the spring/summer months. Also what do they actually mean by "abrade"? If you really think neither of these is a good choice please do let me know. You mentioned earlier in this posting that I should bed the greenhouse path in a 8:1 (8 parts sand:1 part cement) lean mix concrete. Does this also apply to the mowing strip? Also what mix should I use for the pointing between the bricks/pavers? I would also like to include lime in the pointing mix if you think this will make the finish look nicer and be easier to maintain long term. If so what should the mix be? I've also decided to go for the strip footing but without any walls. The greenhouse frame will be bolted to the footing. I've got someone coming round on Saturday morning to go through exactly what I want so that he can give me a price. I'll let you know the outcome. Thanks for your help as always. Max |

||||

|

Tony McCormack Mar 3rd 2003 |

Hi Max,

well, I think you can get better value brick pavers than the Old Mill facing bricks, and the catalogue is right about them 'abrading' (wearing away) under regular traffic, but, for what you're planning, I think you'd be OK, as it'll only be you doing a bit of pottering, won't it? Have you been quoted a price on these items yet? You can use the 8:1 bedding for the path and the mowing strip, and then use a 3 or 4 to 1 mix of building sand with cement for the pointing.

Take photos during the works - it's always good to look back on just how much of a change is made by putting down a bit of paving and a mowing strip. |

||||

|

Max Ali Mar 4th 2003 |

Thanks Tony. Price from TP is about £450 for bricks (inc vat) and £366 (inc vat) for the pavers. This is for about 9 sq. metres and includes 1 metre "wastage".

You're right: my wife and I will only be pottering about in the greenhouse. I've got a fairly heavy duty mower to go over the mowing strip. This is going to be one expensive greenhouse when it's finished. I'll get some pics. on a digital camera and send them to you. |

||||

|

Max Ali Mar 10th 2003 |

Dear Tony,

I went to see the Old Mill bricks in real life and didn't think much of them. I have now decided to go for the Marshalls Chapelgate clay pavers instead. The builder came round on Saturday to discuss the base and he said the best solution was to put down strip footings and then lay up to 2 courses of bricks to make the base level with the surrounding ground. He will also put down a 400mm mowing strip and 800mm path in the greenhouse. Either side of the path he will lay down a membrane and put 10mm gravel. I have 3 questions for you: 1. Since some of the brick course might be below ground level will he need to use engineering bricks? I have asked him to use reclaimed bricks but I'm not sure if it is possible to get reclaimed engineering bricks. 2. Is it ok to lay the clay pavers on a weak mix? Or do they have to be laid on sand? 3. When it comes to using building materials such as sand and cement does it matter if they are branded products from companies such as Blue Circle or are the "own brand" items from Wickes/B&Q just as good? Thanks for you help again. PS. The 2 quotes I've had so far are £980 and £3000. The second company has done a lot of other building work for me to a very high standard and think it will take about 6 days. I've not used the cheaper one but they were recommended by the place where I brought the greenhouse from and they say it will take 2 days. Thanks as always for your advice. |

||||

|

Tony McCormack Mar 10th 2003 |

Engineering quality bricks are the best choice for brickwork in contact with the ground, but you can probably buy new engineering brick for less than you'd pay for reclaimed. If the brickwork is not going to be seen, you could use concrete commons or trenchblocks to keep down the cost.

Seeing as your path is quite narrow, I'd suggest laying all the pavers on a lean mix concrete as shown in the sketch I posted earlier in this thread. Lay the pavers onto the lean mix, tap down to level using a clonker (a small rubber hammer) and then just brush in jointing sand. No need to use a plate compactor, as that would only scatter the pavers. There's no real quality difference in using B&Q branded sand and cement, or sand and cement from a BM, as sand is sand is sand, and cement has to comply with BS12 to be sold as cement. For the type of work you're undertaking, the B&Q stuff will be fine. Finally, 3 grand and 6 days seems a little bit OTT to me. The quote at just under a grand sounds far more realistic. |

||||

|

Max Ali Mar 10th 2003 |

Thanks for the advice. The bricks will be partially in contact with the ground because they are being used on a slope to create a level base for the greenhouse to rest on.

Anyway I'm going to give the go-ahead to the cheaper guy to do the work. |

||||

|

Tony McCormack Mar 10th 2003 |

OK - let us know how it goes. | ||||

|

Max Ali Apr 16th 2003 |

Hi Tony,

The base was completed last week. It looks good although a couple of blocks were cut to size at the front of the greenhouse when they could have been done at the rear where they would have been less visible. Anyway once I get some pots on top they will hopefully be hidden anyway. The blocks were laid on a wet mix as you suggested. However, there is a gap between the blocks which has not been filled. Can you please tell me whether dry kiln sand should be used or something else? The greenhouse goes up on the 26th. I have got a couple of pics for you and will send them when the greenhouse is up. By the way what started as a straight forward project went over-budget because the contractor had miscalculated the slope. He said that I need a 6 course retaining wall for the block paving as the slope was too steep. I agreed to it reluctantly since I just wanted to get the job done. Otherwise I would have had to get more quotes which I am sure would have not been less than even the revised price. |

||||

|

Tony McCormack Apr 16th 2003 |

Just in time for the main growing season, Max! Let's hope the summer is as glorious as is today - if it stays like this until November, I'll be a very happy Tony! Use kiln-dried sand for the jointing - it'll be fine in a greenhouse. Looking forward to seeing the pictures - looking out of my window, I can see that the door to my GH is still shut, and my beloved fuchsias will be sweating in this heat, so I will now slope off and have an hour in the sun with them, and make sure the ventilation is right. |

||||

|

|

|

|

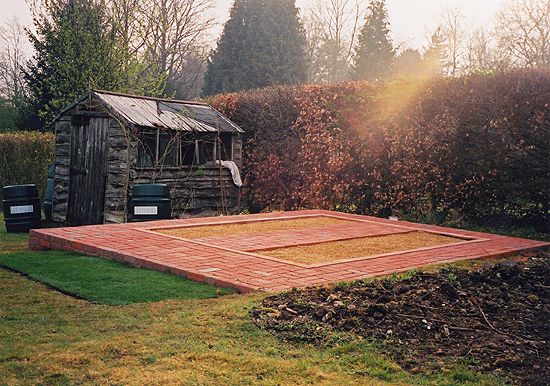

Tony McCormack Apr 25th 2003 |

Max's greenhouse base....the GH itself is due for a big erection tomorrow!

|

|

|

|

|

|

|

|

|

White Rabbit177 Oct 5th 2003 |

THAT IS BEAUTIFUL!!! | ||||

|

Tony McCormack Oct 6th 2003 |

I was lucky enough to see the finished article over the summer. The base was paved using tumbled clay pavers, and Max's Greenhouse is now in place and bursting with plants....

...the tumbled clay pavers look really good in this sort of project. They bring natural colour that ties in with the local area, while their aged appearance, brought about by the tumbling, makes them look as though they were always part of the garden and aren't something radically new and modern. |

||||

|

Max Ali Oct 9th 2003 |

Hi Tony,

It's all been cleared out now that winter is coming. We're already planning how well organised we'll be for next year. |

||||

|

|

|||||

|

Corner mounts for raised slab paving - MRB - Feb 19th 2003 | ||||

|

I'm trying to find a stockist of corner mounts for paving slabs so I can lay a paving floor on what is effectively a roof (a block and beam floor over a cellar below).

I'll waterproof a concrete skim below for run-off, but want to keep it light, and don't want to lay the slabs on sand/ cement. Can anybody help, please? |

|||||

|

|

Tony McCormack - Feb 19th 2003 | ||||

|

Caro is the company your want - they manufacture those little roof support jobbies for flags/slabs and will be able to put you in touch with a local distributor.

Try their website or telephone 01223 208600 |

|||||

|

MRB Feb 19th 2003 |

Excellent - many thanks. Now I just have to sort out the drainage and find a nice, dark grey English stone that can be cut to shape! | ||||

|

Tony McCormack Feb 19th 2003 |

Why English? Is there some reason you can't use an imported Indian stone? Stoneflair have a lovely dark grey imported stone flag in 4 sizes. | ||||

|

MRB Feb 20th 2003 |

I'm trying to keep the project local, where possible. We've used Welsh slate (which is on the roof, too, of what was once a factory, now our house), and other 'green' materials.

I'm hoping I can get something from Purback or Portland (the latter isn't very dark, or grey, come to that!). But, if I don't find anything, Indian it may well be! Best wishes. |

||||

|

Tony McCormack Feb 20th 2003 |

Have a look at the British Stone website - they have a list of virtually every flagstone quarry in the UK, along with info on the colour of the stone produced. |

||||

|

|

|||||

|

Paving moulds - Gunner - Feb 19th 2003 | ||||

|

Hi there Tony

I am writing from the frozen land if Ohio US. I am trying to buy and export some paving moulds, Riven, Yorkstone Rotunda etc to the States. I previously used Harristone for my molds when I had my business in the UK, and he is still around but does not have any of the fencing moulds I am looking for. Do you know of anyone else who sells these type of moulds in the UK?? Thanks - Gunner |

|||||

|

|

Tony McCormack - Feb 20th 2003 | ||||

|

Two of the leading companies are...

Numold of Gloucester - +44 1452 384820

Or you could try Armcon in Stockport - +44 161 429 0011 Their websites aren't up to much, but I can give you full snail mail addresses, if you need them. |

|||||

|

|

|||||

|

|

|

|

Brew Cabin Archive navigation dhtml courtesy of Milonic |