Posted: Sat Dec 21, 2013 9:01 pm

I am currently quoting on a floating seat, like in the picture below:

Although our seat does not have the right end wall like the picture!! Brilliant.

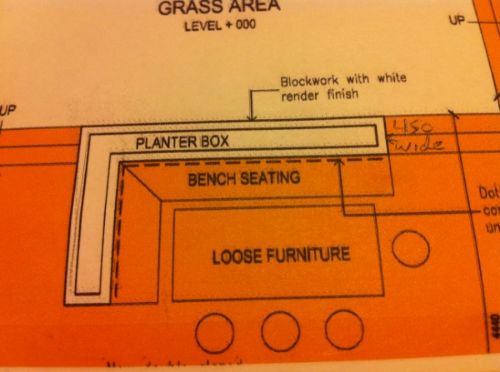

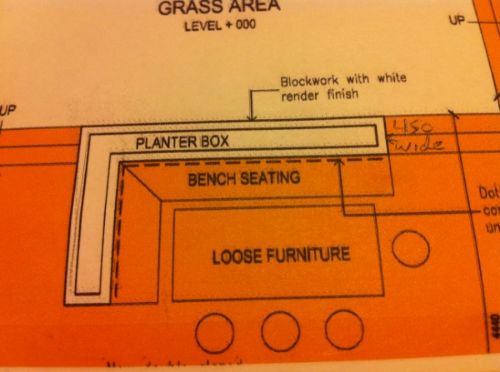

Here is the drawing:

The orange area is decking, which will be +570mm above the grass area. The current ground level where the decking will be is the same as the grass area.

So the overall height of the planter from current ground height will be approx 1400mm, with a seat height of 1020mm from current ground.

S the planter will be quite considerable in height from the grass area/current ground height and the planter is 440mm wide.

There will only be 400mm approx of masonry above the seat height, and it will be constructed of a 100mm block front and back leaving a 140mm gap in the centre for planting.

Question obviously is support for the seat!

This is what I am thinking:

Built from block, 2 parallel courses of block layed flat as the planter is 440mm wide. This will be built up to the height of the seat. So it will really be one solid structure up to that point.

My problem is, there isn't enough masonry above the seat for me to cantilever steel plates or angle irons for the seat support.

I am proposing to have a series of steel supports made up like so:

Each support is a 250x250mm, 6mm flat plate with a 70mm x 8mm flat bar say 1200mm,(I can cut down on site) welded from the centre of the plate coming vertical.

I will build the plates under the first course of blockwork, so all the vertical flat bars come up through the centre joint in the blockwork.

At the point where the seat needs constructing, some 4x3 angle irons with an end plate welded to one end to be built in to each perp of the block, (so every 440mm) and bolted to the vertical flat plate.

Kind of like this:

There will be a timber skirt of the seat to hide the ends of the steel work.

Just after peoples thoughts?

Many thanks & Happy Christmas!

Allan

Although our seat does not have the right end wall like the picture!! Brilliant.

Here is the drawing:

The orange area is decking, which will be +570mm above the grass area. The current ground level where the decking will be is the same as the grass area.

So the overall height of the planter from current ground height will be approx 1400mm, with a seat height of 1020mm from current ground.

S the planter will be quite considerable in height from the grass area/current ground height and the planter is 440mm wide.

There will only be 400mm approx of masonry above the seat height, and it will be constructed of a 100mm block front and back leaving a 140mm gap in the centre for planting.

Question obviously is support for the seat!

This is what I am thinking:

Built from block, 2 parallel courses of block layed flat as the planter is 440mm wide. This will be built up to the height of the seat. So it will really be one solid structure up to that point.

My problem is, there isn't enough masonry above the seat for me to cantilever steel plates or angle irons for the seat support.

I am proposing to have a series of steel supports made up like so:

Each support is a 250x250mm, 6mm flat plate with a 70mm x 8mm flat bar say 1200mm,(I can cut down on site) welded from the centre of the plate coming vertical.

I will build the plates under the first course of blockwork, so all the vertical flat bars come up through the centre joint in the blockwork.

At the point where the seat needs constructing, some 4x3 angle irons with an end plate welded to one end to be built in to each perp of the block, (so every 440mm) and bolted to the vertical flat plate.

Kind of like this:

There will be a timber skirt of the seat to hide the ends of the steel work.

Just after peoples thoughts?

Many thanks & Happy Christmas!

Allan