Page 1 of 1

Posted: Mon Jul 27, 2009 7:16 pm

by Bilabonic

Hi

Started my belle mixer today no problem, put 5 shovels in and it started to make a racket and then tripped.

Removed cover and found belt slipping. If i put light pressure on it to apply tension it (via screwdriver...lol) works fine.

Do the belts stretch on these ? The reason i ask is that i think the motor has moved !!!!

I can see evidence of overheating on the 4 motor mounting bolts that attach to the plastic frame, the frame is slightly melted and looks as if the fixed motor has slipped/moved !!!

Anyone had this or get any thoughts on what i can do ??

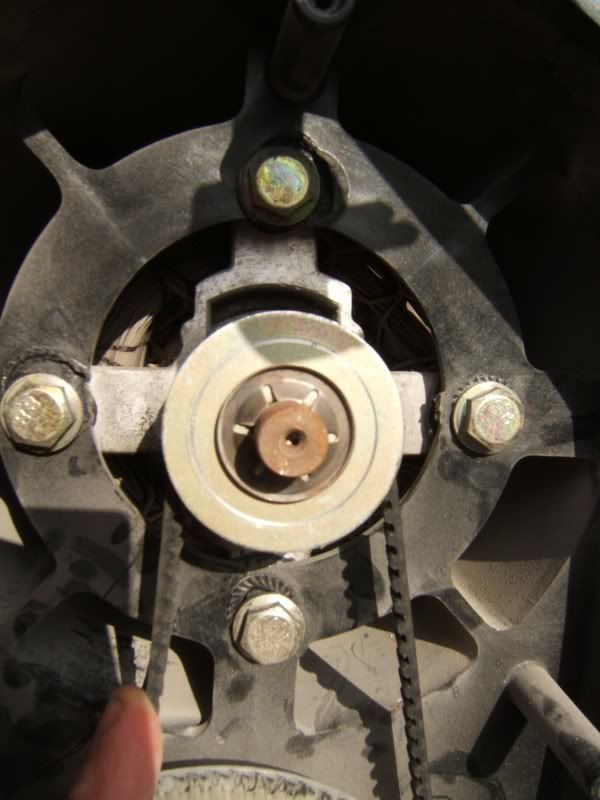

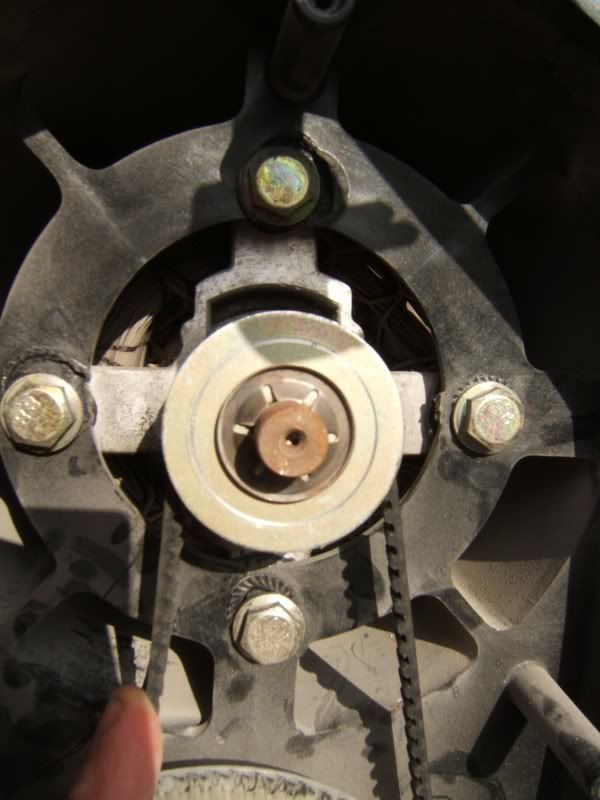

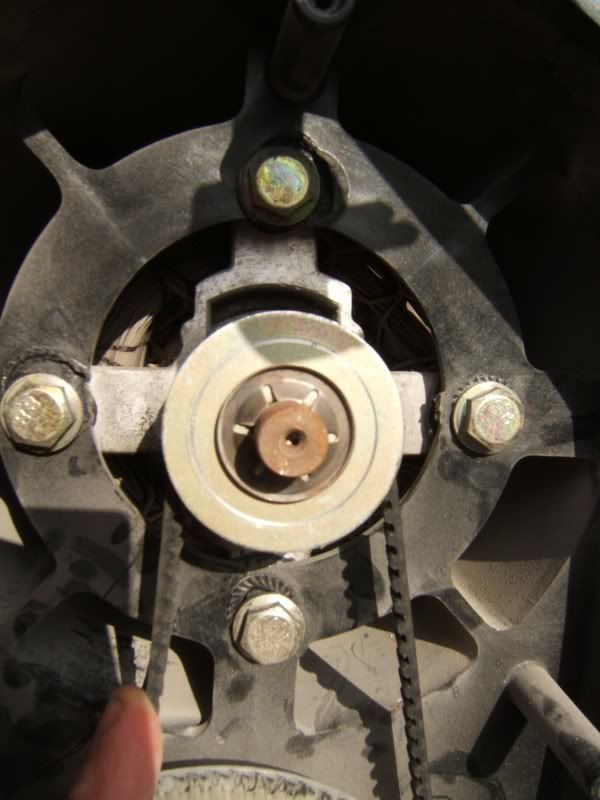

Here are some pics, motor is top, you can see the melting on mounts.

If i put tension on like this with a screwdriver it run fine, you can see how loose it is.

Close up of motor mounts. I have loosened bolts and tried a bar to move the motor but it will not budge....

Cheers

Posted: Mon Jul 27, 2009 7:28 pm

by GB_Groundworks

mine chewed the gear box to pieces the other day, had to get a new main drive shaft and sprocket and to adjust the bel on the petrol you just lift the engine up higher and re tigthen the bolt.

Posted: Mon Jul 27, 2009 7:48 pm

by Injured

Must be the time of year cos the gearbox shattered on my petrol belle last week. Fortunatley it is covered as it 2008 model so cost nowt to replace. Wasnt happy though

Posted: Mon Jul 27, 2009 7:53 pm

by henpecked

You can see where the bolts have slipped. I'd be inclined to strip it from the rear and remove the motor all together. Its probably over heated and melt the plastic a bit, therefore, you cant get it to slide laterally without first removing the motor totally.

Hp

Posted: Mon Jul 27, 2009 9:20 pm

by dig dug dan

My belle finally gave up. I have the one on the stand with the wheel to turn the drum, and it fell off the truck again, this time bending the motor housing. It caused the two inner cables inside the wire to strip and fuse together, so when i plugged it in, it caught fire. Then i tried to spin the drum over, to discover the bent motor housing was fouling it, and the drum stopped turning under load.

It was never right after i lent it to someone.

On the phone straight away to order a new one, although i tried to buy a more expensive italian model, but they were out of stock, so back to belle! (Tried the clarke, what a waste of space)

Anyway, back to the point , i don't think there is any adjustment on that model, but you can buy a new belt, which will be tighter. any local dealer should stock them

Edited By dig dug dan on 1248726105

Posted: Mon Jul 27, 2009 10:35 pm

by Bilabonic

It does look as if there is no adjustment, i have removed the bolts but the motor sits in a plastic fixed support, it has also melted into this and stuck fast. This is not visible on the pic.

My first belle after years of no trouble with my el cheapo BQ....

Posted: Mon Jul 27, 2009 10:40 pm

by GB_Groundworks

we've got a big belle 240 litre diesel one on site and has been mixing for about 3 to 4 years now everyday almost with out any problems touch wood, some kids filled the diesel tank with sand once but thats it. must get 5-10 mixes a day knocked up on it on my dads sites. can't fault that but had 2 smaller ones fail me, had to change the drum on one which involved welding a big bit of angle iron to get it off haha.

Posted: Tue Jul 28, 2009 8:46 am

by Bilabonic

Well some people are telling me its adjustable and pivots on the rhs bolt ?

Posted: Tue Jul 28, 2009 10:10 am

by Bob_A

Posted: Tue Jul 28, 2009 10:25 am

by Bob_A

Does this help?Taken from page 22

minimix 150 from july 2009

All Belle mixers Electric/Petrol are fi tted with a preset tensioned toothed belt. No adjustment is

necessary. DO NOT try to adjust with the motor running. Ensure the extension lead is always unplugged

before the motor cover is removed.

Taken from page 6

minimix 150 pre july 2009

Mini 150 electric version: To adjust slacken the

main motor bolts, raise power unit and retighten

bolts, once the belt is adjusted correctly, it should be

possible to move the belt by 7-10mm. Always

replace the guards.

Petrol version: Slacken main engine base to

gearbox bolt. Raise power unit to tension belt and

retighten. Once the belt is adjusted correctly, it

should be possible to move the belt by 7-10mm.

Always replace guards