|

|

|

|

| Block Paving - Page 07 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Small puddle on finished pavement - Richard Malin - 15 Mar 2002 | ||||

|

Hi Tony,

drove past a previous job today - it was raining heavily so couldn't think of many other things to do - and noticed a small pocket of water retention. The job is a driveway of around 2.5m wide x 20m long, done in Brett's 3 size rumbled alpha. When we started this job I noticed the drive was almost flat but as there was no other easy way around it I set it out to fall the water to the pavement, with a slight twist towards the lawn after the end of the bungalow. I don't suppose the owners are too bothered, but what do you suggest to prevent this happening in future? The fall on these blocks is at a guess 4" over 20m , a lot less than your recommended minimum of 1" over 2 metres. Thanks, Richard. |

|||||

|

|

Tony McCormack - 15 Mar 2002 | ||||

|

The simple answer is to increase the fall. 100mm in 20m is a scary 1 in 200, which is, as you note, well below what I would normally suggest.

Although you can get away with ridiculously tight falls with a well-laid block driveway, if you get a few mil of settlement in 2 or 3 years time, it can result in what looks like a big pond, but is actually only a rizla-thin sheen of water. Still, the property owners are on the 'phone and other passers-by have spotted your "lake". When we come up against this sort of tight fall, I always err on the side of caution and bang in an extra gully or a length of linear drain, and then set out the falls to direct the water to these new drain points, along with the existing gullies, the public footpath, garden etc. It may put your overall job price up by a few quid, but I always found the better clients were more than happy to pay for an extra gully if it meant they had a well-drained drive that would give them many years of trouble free service. I'd rather do that than take the risk of having to be called back to install a gully 12 months later, often at your own expense.

So, try to keep falls to 1:80 minimum, and if that's not possible, look to install additional drainage so that the min fall can be achieved. |

|||||

|

Richard Malin 18 Mar 2002 |

Hi Tony,

thanks for that. Drove by again today and knocked the door, explained that guilt had got the better of me and would come to repair the dip as soon as the weather was dry. Old folks made me some tea and seemed quite bewildered!

Ta, I'll survey it better next time ! |

||||

|

Suki 27th Feb 2003 |

Hi Tony just a quick query, at what point does surface water on block paving become classed as puddles and not suface water making it way to the drainage point? I have a job where the gradient is very slight but enough to move the water on but the water moves pretty slow and on the way probably gets to about 3mm deep while it raining heavy. Would this be classed as puddles and thus unacceptable? Your thoughts are much appretcated. |

||||

|

Tony McCormack 28th Feb 2003 |

I'm not sure if there is an official definition for block paving, but a Clerk of Works I used to harrass while working on sites with with my Dad when I was just a lad in the 1960s always used to say that if standing surface water covered a penny (and these were the old 1d pennies), then it was 'ponding' and would have to be relaid. I reckon that still holds good today, even with the decimal pennies, which are around 2mm thick.

Standards are slightly different for different materails. I know that machine laid bitmac has a pretty tight tolerance (3mm in 3m, IIRC) but tolerances for elemental pavings are not as 'tight' and 3-6mm in 3m would be more usual.

I still prefer the 'penny test' though. |

||||

|

|

|||||

|

Plastic edges for block paving ? - Jason Shaw | ||||

|

Hi,

Some time ago I saw on a DIY program a plastic type edging strip which is layed on either side of a block paving path, fixed by stakes or something which gives an edge to pave upto. It could also be fixed in a curved position which made sure the path stayed parallel. Has anybody used this product or know where it could be purchased (or did I dream it!

Many thanks,

|

|||||

|

|

Tony McCormack | ||||

|

Hi Jason,

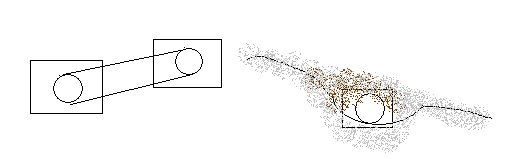

this sort of edging is very popular in the US, but there's only one real 'seller' over here, and that's 'Keyform' from Marshalls. This "Keyform" utilises a pre-formed plastic restraining strip that is, literally, nailed to the ground with the aid of 300mm steel pins. Each restraining strip is 4m in length, and can be cut to size as required. Longer runs can be created by linking together adjacent sections with a special joining member that slots into each piece. I'm actually in the process of building a page describing it's use and Marshalls have allowed me to feature pics of their product, but I'm still waiting for confirmation from the US companies that I can show their products to give a fuller picture of the whole range. Maybe next week! :) I've also heard from a new UK seller, Hauraton Kaskade and they have just launched a rigid and a flexible edging restraint onto the market, selling it under the name of "Linefix" Edgings. The flexible strip is used for curves, the rigid for straights. You can email them for more info via Anyway, why aren't they popular in the UK? There's aquite a few reasons, but the main one is cost. They are relatively expensive compared to concrete bed and haunch, and can take longer to set up correctly. Personally, I wouldn't waste my time with them, but I do appreciate their use in specific conditions, especially areas subject to heavy freeze-thaw cycles. This is an excerpt from the page under construction...

The great advantage of this type of edge restraining system is that it allows soil to come right up to the edge of the pavement. However, as can be seen from the cross-section drawing above, this is only a relatively thin covering of soil, as the sub-base should extend beyond the edge of the pavement. In fact, if the sub-base is extended to 200mm beyond the pavement edge, this is considerably more spread than the typical 100mm width of haunching concrete

While Keyform and similar products undoubtedly have their uses, they do not have much of a market in the UK for a number of reasons...

Follow up the UK leads, if you wish, but 'phone your local BM and get them to quote you a price before you commit. If you can hang on a week or so, the new page will be up by then. ...later... The page is now uploaded and live, Jason.... http://www.pavingexpert.com/blockedg.htm

...I'd be interested to hear your thoughts. |

|||||

|

|

|||||

|

Block Paving Contractors in East Mids - Andy Wright | ||||

| Does anybody have experience of block paving contractors operating in the East Mids area, specifically Nottingham? Good and bad experiences welcomed | |||||

|

|

Tony McCormack | ||||

|

The following contractors are all members of Interlay, the official Trade Body for block paving. You'd be hard pushed to find better.

Alan Parkes Gardencare

Bishops Landscaping

Duo Paving

Newberry Construction Ltd.

TECNi:BLOCK

|

|||||

|

|

|||||

|

Armstrong's Blocks - Nigee - Dec 2nd 2002 | ||||

|

Just laid a driveway. Customer bought the blocks - Thomas Armstrongs Armpave 50 in Brindle - 200mm by 100mm by 50mm. The blocks were 2nds !!! What a pain in the ass to lay. The sizes are all over the place, some blocks are 45mm thick - some are 55mm thick, some are 2-3mm wider than the rest - you get the idea!

They were 2nds because Armstrongs have just started to produce these blocks in England and they apparently got the colour scheme wrong for the Brindle. I would say that they need to look at their moulds for the sizing of the blocks. They have been flogging them for £6 m² + vat as 2nds. Just a word of warning for all you contractors - Keep away from these blocks. It took me an extra 2 hours on a 40m² drive just to align the blocks. They might be cheap, but they are NASTY. Also Armstrongs make a Silica Sand - what a joke !! The sand is orange and when damp is just like Building Sand. It looks awful on a newly laid drive. You can't beat Travis Perkins Kiln Dried Sand for quality and looks. I have used a number of different brands of 200mm by 100mm block and I find Marshalls to be the best quality. |

|||||

|

|

Tony McCormack | ||||

|

Are these concrete blocks? Armstrong's don't send their blocks much further south than Lancaster/York, so we rarely see them, which, from what you say, may not be a bad thing. I know several contractors really like their Beamish Cobbles, though.

2nds are always a huge gamble. We had a client in Ormskirk some years ago who bought 3 full loads of oversize blocks from Charcon/Camas and the couple of quid per metre he saved on the blocks was swallowed up by our labour cost, as we spent hours trying to get them aligned, trying to get rid of 5-10mm wide joints, and farting about the variation in thickness. Properly laid, CBPs should last a good 20 years - is it really worth skimping and trying to save a few quid by using reject blocks? After our experience in Ormskirk, we won't take on any work involving rejects, seconds, overbakes or any other block/brick that's not perfect. Life's too short! The ArmPak jointing sand is not that bad, I find. The colour disappears after a few weeks, once the crud settles over the surface, and at least it is a properly graded sand, unlike some. The colour of jointing sands (and bedding sands) varies throughout the country. The ArmPak doesn't get used Darn Sarff, where the sands tend to be much more yellow. Personally, I like the washed Mersey Grits - a nice neutral silvery-buff colour that doesn't stain the blocks and it drains really well. |

|||||

|

|

|||||

|

Removing blocks - Deefa - Jan 6th 2003 | ||||

| I have to remove about 6-7 blocks from a finished drive due to oil staining. What's the best way to lift them out? I understand there is a tool on the market specifically for this? Any ideas on prices of such an item or do you have any tricks of the trade to help with this? | |||||

|

|

Tony McCormack | ||||

|

What you want is the Repair Page....it shows you how to do it with basic tools, in diagrams and photies.

The 'Block Extracting Tools' are brilliant, if you have 65 quid to spare and will be using them regularly, but two trowels is just as good - in fact, they're even better on established paving! Let us know how you get on - the frost will make them a bugger to loosen! |

|||||

|

|

|||||

|

A Bigger than average job... - Mungoh - Jan 10th 2003 | ||||

|

At the front of our house we have a driveway already created in buff-coloured pavers. The driveway is the minimum-width required for a car, edged with bricks on to a garden area (moss, not grass) of about 5 metres width. With three sons of ages 10,12 and 14 I foresee three extra vehicles in the not-too-distant future, plus their interest in roller hockey would also be helped if we paved over the existing garden too.

The resulting finished area (finished in my mind as of yet) would be approximately 8 metres wide and about 20 metres long. How do I go about screeding that area (replies such as "bl**dy slowly" being presumed I was considering three longitudinal "slices", putting in two linear drains and doing a sort of "divide and conquer". Do I lift all existing pavers and then mix these in with new-bought ones, or buy all-new pavers?

I've got a raft of further questions, but these might be consequential on the answers to the above.

|

|||||

|

|

Tony McCormack | ||||

|

MungoH writted.... 8 metres wide and about 20 metres long. Do I lift all existing pavers and then mix these in with new-bought ones, or buy all-new pavers? If you chuck away the older blocks, you're paying for a skip as well as new blocks, and it's environmentally naughty in these landfill-conscious times. Mixing in the older blocks with the new ones will make the new, extended driveway look spotty (much like one of your teenagers, I s'pose!) for a few weeks, but, 6-12 months later, you'll be lucky to identify the older ones.A good tip is to power-wash the old blocks before you lift them. This makes sure they're in tip-top condition when they come to be relaid, and the weathering will be even less noticeable. Do the power-washing on the OLD drive - you shouldn't power-wash new block paving until it's sealed itself or been coated with a proprietary sealant or joint stabilising compound. |

|||||

|

Mungoh Jan 10th 2003 |

The twenty metre length is along the gable-end of the house (plus double garage etc; the house ain't that big) so I'd think that working "long-ways" might make it easier to build in a slight fall away from the house?

Tony wrote... "Mixing in the older blocks with the new ones will make the new, extended driveway look spotty (much like one of your teenagers, I s'pose!) for a few weeks, but, 6-12 months later, you'll be lucky to identify the older ones." The presumption being that I can source blocks with an identical colour (or as near as damnit) to the originals. And identical size too.If I create the new paved area with a slight fall away from the house, is the idea of a couple of "train lines" of linear drainage overkill? The present driveway sits with puddles on monsoon day, so I'd rather install some drainage than leave the rainwater to percolate away. Would the linear drain lines detract from the overall appearance, or would it break up the visual impact of a big block of pavers? The web-site alludes to the fact that some people install patterns on the paving (house numbers, etc). This sounds fine unless you accidentally encourage a 747 to land on your drive! Looking down our drive, the main house door is recessed from the gable end to the point that new callers are initially puzzled as to where the front door is. Beyond a large arrow, any alternative ideas to encourage a "this way" feeling? Further, I was impressed on a visit to Norway that main buildings there sport a sort of "cattle grid" at the entrance to attempt to remove snow and soil off the soles of the pedestrians before they enter. Any source for such a metal threshold grid, or do I just contact a local blacksmith? And then.... "You shouldn't power-wash new block paving until it's sealed itself or been coated with a proprietary sealant or joint stabilising compound." Presuming that modesty forbids you to mention any particular manufacturer's product, how are us novices to know which products are worth the dosh if we ain't given (say) three alternatives?Recently I received the Jewsons catalogue for paving. The prices in there are about 11 quid per square metre for the pavers. Is this reasonable, or one of Jewsons (and other) manufacturers regular ploys to maximise their profits to the unsuspecting DIYer?

Ta in advance; told you I'd have more questions! Mungo |

||||

|

Tony McCormack Jan 11th 2003 |

Screeding:

Working the screed lengthways would be easiest. You have a level defined against the the house itself, so you need to define the outer edge, and then establish the central screed rail. As you're only establishing one screed rail, then the chance for error is much reduced. And yes: it does have to fall away from the house. You will need some form of drainage at the low point, which could be on the outer edge or perhaps even a length of linear drain along the centre line.

Mixing Older Blocks

Size-wise, there should be no problem as the vast majority of concrete block paving in the UK is made to a standard size and are interchangeable with units from other manufacturers (in the case of the standard rectangular 200x100 blocks, that is).

Linear Drain

However, having just one unit of a linear drain plonked somewhere within the paving would look bloody daft, so you could consider....

...as you can see, there's more than one way to drain a pavement, and you need to decide which suits the project and your pocket. You need to consider the outfall points, ie, where the water will drain to, but all the above options are, in my opinion at least, aesthetically acceptable.

Enhancing the Front door

Pedestrian Cattle Grid

Choice of Products

Send me a pic of your house, tell me whereabouts you live, and I'll give you a "Tony's Top Three" but the final choice should be yours. 11 quid per m² for a multicoloured 200x100 paver is fair. You can actually buy for less if you're in the trade (around 9 quid per m²) but that's only to be expected. |

||||

|

|

|||||

|

Guesstimating for a 2:1 Pattern - Socal Scott - Jan 14th 2003 | ||||

|

Very relieved to find your site, for I am a newbie. I've sub'd for a company for about 5 installations. I'm told the work has the best detailing in the company, but I've left the nest (no profits) and currently need to figure out a 2:1 ratio, random runner pattern, ASAP. 2 squares to 1 rectangle. Stuck on number of pallets/skids to order...Grrr

Thanks and I'll be frequenting these haunts per the newbie status. Awesome site and efforts. |

|||||

|

|

Tony McCormack Jan 14th 2003 |

||||

|

Hi Scott,

I'm not sure what you mean by a "2:1 ratio random runner pattern" - maybe it's a term unique to your country. For any pattern, I would need to know the block sizes involved, so that I can work out the placement. You mention squares and rectangles - is it a situation where 2 squares cover the same area as 1 rectangle?

In Europe, paving is bought by area rather than number of blocks, which makes things much easier. |

|||||

| Socal Scott - Jan 14th 2003 |

It would be nice if 2 squares equaled a rectangle.

Rectangles = 140mm x 140mm

The pattern is:

Since individual patterns incorporate a varied number of pieces and areas, I am hoping there are formulae which require the input of any given number of pavers a pattern consists of and each pavers area. Thanks again |

||||

|

Tony McCormack |

Right - I'm with you now. Sort of!

With a random pattern, the ratio of squares to rectangles is variable. However, as the paver layer, you are in a position to determine that, for example, there will be twice as many squares as rectangles. So, in such a case, the way to calculate the number of pavers required is....

Ratio = 2S:1R

...in terms of ordering, divide the total area of the job by 2.3. The result is the total area of Rectangles required, and then simply multiply by 1.3 to determine the area of Squares. F'rinstance, you have a 150m² job to be laid in the 2S:1R pattern..... 150 ÷ 2.3 = 65.2 - so, you need 65.2 m² of Rectangles, and then 65.2 x 1.3 = 84.8m², which is the area of Squares required.

Just to check, 65.2 + 84.8 does indeed = 150 Is that what you mean? |

||||

|

|

|||||

|

Sand Jointing in the wet - MissP - Jan 18th 2003 | ||||

| If it is raining or blocks have got damp, what do I do about sweeping in the kiln dried sand? When I try to do it, it sticks to the blocks. Do I have to wait til a hot summers day?!!! Or will the sand eventually go between the blocks if I put enough of it on? | |||||

|

|

Tony McCormack Jan 18th 2003 |

||||

|

You wait until the surface of the blocks is dry. It might take two or three goes to get the joints properly filled, but, everytime the top of the blocks is dry, you dart out and do all your sanding-up jobs while you can. We had a thread on this a couple of weeks ago - was it PAJ and his never-ending rain??? Just had a look and it was PAJ's thread - take a look at the "Paving in the rain" thread in this archive. |

|||||

|

|

|||||

|

Moss - Ian9 - Jan 20th 2003 | ||||

|

Each Year/6 months I am forced to clean my block paving. The moss just keeps on growing.

What is the best way to clean this (easiest)? Once it is cleaned should I put a sealant down (if yes which one)? Rgds

|

|||||

|

|

Tony McCormack Jan 20th 2003 |

||||

|

Hi Ian9,

you're in luck, posting your message just as I'm on my nightly rounds! Anyway, to kill the moss, you can use Sodium Chlorate, bleach (dilute at 10:1), Jeyes Fluid (expensive) or any commercially available weedkiller. It'll take about a week to kill it off, and then it should be simply a matter of brushing the pavement clean. You could try power washing, but be careful not to blast out the jointing sand, and keep the lance at an oblique angle. A sealant will keep the moss at bay in most cases, and the best sealant depends on the type of finish you want, ie, gloss, satin, matt, and the type of paving, ie, clay or concrete. It's hard to find a sealant any better than those produced by Resiblock. Some sealants may be just as good, but none are better, IMHO. There's more info, and links, on the Sealants page. |

|||||

|

Ian9 Jan 20th 2003 |

Thanks Tony I'll give this a go Ian |

||||

|

Kevin Whitlow May 13th 2003 |

Ian9,

If you don`t want to go down the sealant route your local farm supplier will have 5lbs bags of copper sulphate in granular form for around £8-10. Mix 5 tablespoons of granules to each gallon of water in a watering can. With the rose on and when the moss seems dry treat about April-May just after moss has spored. Moss detests this and the more expensive Zinc Sulphate, should last for 18 months per application. E-mail me if you have problems buying 95-98%strength, I`ll find you details of a supplier. Only thing you must watch is your fish pond! Not as harmful as bleach etc to pets, plants and little ones Hope this helps! |

||||

|

Tony McCormack May 14th 2003 |

I've not tried copper Sulphate, Kevin, or at least if I have, I wasn't aware of the fact, but I wonder does it have the same problem with concrete as does Iron Sulphate, which is a popular ingredient of "lawn feed'n'weed" products?

Iron sulphate produces nasty rust-like markings on concrete and they are more or less impossible to shift. Is that because of the Iron, the Sulphate, or a combination of the two? |

||||

|

Kevin Whitlow May 15th 2003 |

Hi Tony, I`ll try and expand a little on my reply.In the past I`ve tried-Sodium Hypochlorite, household bleaches, formalin, copper nitrate, ammonium sulphate, and trisodium phosphate. All of these chemical agents are suitable for bio-chemical stains i.e.moss, algae,fungi (I`m a fun guy!) lichens of certain types. In my humble experience copper sulphate is cost-effective, with limited impact on the surrounding environment. As you quite rightly pointed out iron sulphate can stain concrete, in fact isn`t it the case some people purposely stain concrete for effect with this substance?

Copper sulphate can equally stain concrete at dilutions of 80% a mild green colour,a 3-5% aqueous solution (the formula I suggested) will in no way stain. I`m sure you`ll agree sealing a driveway is always better in the long run (prevention better than cure) if you have the foresight to spend the extra few bob soon after installation or cleaning, my problem is that people see the up front costs,not the long term benefits.

Did I say I`ll expand a little? Gone on long enough! |

||||

|

Tony McCormack May 15th 2003 |

I know iron sulphate is used as a base for many of the concrete staining techniques that are becoming more fashionable, but I suspect that it is at a much higher strength than would be found in lawn treatments or mosskillers, but then, you never know!

I remain ambivalent about sealing driveways. It's a wise investment if you want to keep those neat, pristine looks, and it's essential for some surfaces, such as PIC, but for natural stone or the more rugged/natural looking pavements, I don't think it's all that important. It really is a matter of personal taste, I suppose. |

||||

|

|

|||||

|

Kerbs for a driveway - Liam Booth - Jan 21st 2003 | ||||

|

Hi, I am currently considering laying a simple block paved drive, but however I am unsure on one aspect. I would like to lay key kerb edge restraints either side of my drive, but I am unsure when you should lay them, and what happens when you come to screed the sand. If the kerb unit was 200mm high and I wanted the kerb to be 100mm higher than the blocks once compacted, how would I set up the screed level? |

|||||

|

|

Tony McCormack Jan 21st 2003 |

||||

|

Easy! Lay your kerbs as detailed in the kerbs/edging section of the site, and then lay a soldier course of blocks against the kerb, 100mm down from the top, on a 10:1 grit sand/cement mix. You can then use those soldier courses to screed from, with a notched board, as you prepare the laying course for the rest of the paving.

Does that make sense?

I know some contractors lay the kerbs as an afterthought, but we find that, with no firm haunch, the edges of the pavement can drift during construction, and then you're waiting for the haunching to harden before you can consolidate the paving, whereas, if you lay the kerb first, the backing concrete has set by the time you've laid the rest of the blocks. |

|||||

|

|

|||||

|

Cost of an average block paved drive - Liam Booth - Jan 26th 2003 | ||||

| I would like a new driveway laid in blocks, and I am wondering how much on average is it likely to cost. The total area of the drive is 40m² so I have calculated that I need 2000 blocks. We already have a tarmac drive so we can use part of that sub- base. Also I would like a key kerb around the perimeter of the site. If you have any views post a reply!!! Thanks. | |||||

|

|

Tony McCormack Jan 27th 2003 |

||||

|

Some guide prices are given on the main Block Paving page, but you should know that prices vary throughout the country and with the type of block used. Somwehere around 45-55 quid per square metre seems to be the going rate for 200x100 standard blocks paving, althought it can get up to 70 quid and more per m² in the South-east or on smaller jobs. |

|||||

|

Suki Jan 27th 2003 |

We're pretty competetive then at £40 per m².

We did a quote at the weekend for BP and it came to £1800, however the customer said he'd had 2 other quotes for £900 & £1100, so I bid him fairwell. Bloody giblets eh! |

||||

|

Tony McCormack Jan 26th 2003 |

Anyone quoting half of your rate, ie, 900 quid instead of 1800 quid, Suki, has to be a cowboy. The blocks cost a tenner, so how can they possibly excavate and cart away, supply and lay sub-base, supply and lay sand, lay the blocks, cut-in, wacker and sand-up for a tenner?

40 quid per m² is a keen price, just a bit lower than what we see in and around Manchester/Liverpool. However, my survey of national prices includes the made-up big numbers from contractors working in London and the south-east and their prices push the average cost per m² to more or less 50 quid per square metre. |

||||

|

|

|||||

|

Driveline vs Drivesett - Nezza - Jan 29th 2003 | ||||

|

I've had some movement from the council regarding my flooding problem so now my attention is turning to the question of relaying my drive.

I've drawn up some plans which I've put up here. Sorry about the quality of my scan - I'll include some pictures of the house to put the plan in context shortly. Unfortutely all the radii of my bends are between 2m and 3m. I was hoping to lay a soldier course of Tegula Drivesetts around the edge of the gravel area - which by my calculations needs almost 4m radius before you can lay the blocks uncut. Would it look a bit odd if I used charcoal Driveline as the soldier and Tegula for the paved areas? Or should I just bite the bullet and cut some blocks? I've got a diamond blade, water-cooled tile saw which I used to cut the limestone tiles I laid in the kitchen - I think it's 550W - will it have enough oomph to cut concrete blocks or will I need to hire something else? Also, since I've never done anything like this before, is it feasible for me to do this more-or-less single handed if I take a week off work? I might be able to get some help operating machinery (cement mixer, for example).

My estimations are:-

Thanks |

|||||

|

|

Tony McCormack Jan 29th 2003 |

||||

|

Charcoal Driveline looks OK-ish with Drivesett, but it's quite 'modern' looking against the tumbled appearance of Drivesett, which may not be to everyone's taste. I'll have a root through my photo library to see if there's any pics that might help you visualise.

For the soldiers, I'd rather trim Drivesetts than play about with different blocks. Drivesett are quite easy to trim in a splitter and the cropped edge looks more authentic than a sawn edge on tumbled blocks. But, have you considered using 120mm Drivesetts, Drivesett Deco or even Drivesett cobbles? They are small enough to accommodate your radii.

When it comes to laying the drive, I'm sure you could do it yerself, but it might take you more than a week, if you're starting from scratch. With a mini-digger and a bit of good organisation, along with favourable weather, it could be done, but I'll wait till I see your house pix before committing meself one way or t'other. |

|||||

|

Nezza Jan 30th 2003 |

I hadn't really considered the small Drivesetts... I've had another think and they could be the answer. Unfortunately it means laying 730 of them instead of about 550 of the larger ones. On the plus side they're cheaper, and I'll use a bit less concrete.

If I use Tegula for the edges and for the paths, how do I stop the edges of the paths from getting 'lost'? Or am I worrying unnecessarily?

My rough time plan looks like this:- which leaves the following Sat/Sun as contingency. I'm going to have to trust to luck for the weather - and hope that Metcheck is reasonably accurate. |

||||

|

Tony McCormack Jan 30th 2003 |

I wouldn't worry too much about the number of blocks being laid - the area covered and total weight of paving handled remains the same. There's a bit more messing about, but, compared to cutting, it's a lot easier. What do you mean by edges getting 'lost'? If they're laid on and haunched with concrete, there's nowhere for them to go, and they will retain the rest of the paving. With regard to your schedule, I reckon 3 days to lay the soldiers is unduly pessimistic. You should be able to do it in 2 days, but then, I reckon you might need 3 days for the sub-base, the gravel and the paths, so it's all academic, really. The only weather that can stop you is hard frost or torrential rain, and, as far as I know, neither is on the menu for next week. Bloody cold today, though! |

||||

|

Nezza Jan 30th 2003 |

Looks like I'm on the right lines then What I meant by losing the edge was that, since it's all the same material, will it look like there IS an edge, or just that the paving stops - if you see what I mean. In other words, there won't be a border to the paving - oes that matter or will it look OK? I hope I'm making myself clearer. It won't be next week, but depending on when the council say they'll do their part, it could be the week after.

Cheers |

||||

|

Tony McCormack Jan 30th 2003 |

Won't your paths have a soldier course? That should provide edge definition.

Or do you mean "upstand", like a kerb provides? |

||||

|

Nezza Jan 30th 2003 |

Yes, the paths will have soldiers - I'm clearly worrying unduly, then.

The council will let me know on Monday when they expect to start, but since there's a crew in the village doing some kerb work etc at the moment the chances are they'll be able to do their part soon. Neil |

||||

|

Tony McCormack Jan 30th 2003 |

Right! So, what's the arrangement with the soldiers? Have you decided one way or t'other?

If you go with the 160x120mm units, a good-looking wide-ish soldier is a 160 wide block on the outside, a 120 in the centre, and then another 160 on the inner edge...

...as in this detail from a recent design. |

||||

|

Nezza Feb 26th 2003 |

The council altered the footpath profile and built up in my driveway last week, so hopefully no more inundations from next door.

As a result I'm go to do my part the week after next, with a couple of helpers, and I'm looking around for suppliers at the moment. On the aggregates side, Lafarge has a depot in my village so I think it's quite likely I'll use them - I notice that they also have block pavers and wondered if they have anything comparable to Marshall's Tegula - the web site doesn't have any pictures to show their products. As for the arrangement of the edging, I'm going to go with a single soldier course for now. I hope that in a few years I'll be able to afford to take up the gravel and in-fill with blocks, but I can't spring for the extra at the moment.

Regards |

||||

|

Tony McCormack Feb 26th 2003 |

Lafarge are relative small fry in the world of Concrete Block Pavers, but they do have a tumbled product that could be viewed as an alternative to Drivesett. They call it "Courtyard Paving', and in an amazing coincidence, it comes in exactly the same sizes as Drivesett/Tegula, and there's even a 50mm thick version! Amazing, eh? We don't see it up here in t'north-west of England but it seems it's slightly more expensive than Tegula/Drivesett. Lafarge, like almost every other larger manufacturer, will not sell direct to one-off customers, so you'd have to buy via a buliders' merchant, anyway, so give your local BM a call and ask them for a price.

All the other manufacturers have their own versions of a tumbled block - Woburn from Charcom/Bradstone, Alpha from Brett, Clifton from Formpave, Priory/Chelsea from RMC - once one manufacturer has a 'good idea' it's never long before the rest of them are on the band-wagon. so it might be worth looking at other options! |

||||

|

Nezza Feb 27th 2003 |

We did consider the other 'majors' like RMC etc. but SWMBO likes the Tegula, so that's what I'm doing.

Incidentally, I've been quoted £16.21/m sq. for my 22 m sq., inc delivery but exc. VAT. Seems a reasonable price to me. Many thanks for all your advice - I'll take the 'before' photos this weekend and post them with the plans. Cheers |

||||

|

Tony McCormack Feb 27th 2003 |

That's a typical diyers price for ex-yard delivery via a BM.

22 m² is just a bit more than 2 full packs, but the Tegs come with each size in a separate pack, so, to get a decent mix, the BM is going to have to split the packs, or you'll end up with twice as many 120x160s (smalls) as 240x160s (large). Have they told you what 'mix' of sizes they'll supply? |

||||

|

Nezza Feb 26th 2003 |

That price was to my specification - ie 840 small, 110 medium, 80 large. | ||||

|

Tony McCormack Feb 27th 2003 |

Oooh! That's an awful lot of smalls! Is there some reasoning behind your (roughly) 10:1 ratio? | ||||

|

Nezza Feb 27th 2003 |

Most of the smalls are for the 88 lin. m of soldier | ||||

|

Tony McCormack Feb 27th 2003 |

160mm wide? That'll use 8.3 smalls per metre, or 733 small in total, leaving 107 smalls for the body (along with the meejums and larges) so that's not too bad.

You've ordered more or less bang on 22m² with no allowance for wastage or cutting - will you have enough? There's nowt worse than being a half-metre short of finishing, as that only ever happens after the BM has shut up for the weekend! |

||||

|

Nezza Feb 28th 2003 |

Well, the 22m² is allowing for wastage - I think I need 20m² overall so I added 10% safety margin | ||||

|

Tony McCormack Feb 28th 2003 |

You'll have plenty, then. When do you start laying? |

||||

|

Nezza Feb 28th 2003 |

8th/9th March for excavation and marking out.

The concrete is ordered for 10am on 10th March - I've got 3½ people laying blocks so I hope we can get all the soldiers down on the Monday. Tuesday 11th for haunching and contingency. Wed/Thur installing the sub-base - I'll be using the mini-digger to move the DTp1 around the site. Probably install the gravel on Thursday afternoon. Friday to pave the paths (6 m²) etc. Cheers |

||||

|

Tony McCormack Mar 1st 2003 |

3½ people laying blocks? Who's the ½ person?

I think the forecast for the coming week is pretty naff, but hopefully it'll pick up again by next weekend. |

||||

|

Nezza Mar 3rd 2003 |

Well, there's me, 2 definites and a maybe.

I saw the weather forecast and it doesn't look too hopeful, but as long as it's not too bad at the weekend and early in the week we should be OK, I hope. Cheers |

||||

|

Tony McCormack Mar 3rd 2003 |

I'll bet you wish you'd done it this past week! It's been ideal paving weather - not too cold, not too hot and, most importantly, dry. |

||||

|

Nezza Mar 16th 2003 |

I'm absolutely knackered.

More importantly, thanks to you, the drive is more-or-less finished. At last. By Saturday afternoon last, I was wondering what I had taken on. Sunday deepened my despair. At least I had finished the excavatation. And a mini digger. On Monday, Simon and Rob arrived. We levelled, marked out, drank tea, pondered, reflected and knuckled down. I also postponed Mr Mixamate, much to his late-notice disgust.

Tuesday became more marking, levelling and wacking. I had the semblance of a drive; it didn't help me sleep easier. On Wednesday, Mr Mixmate arrived on site at 9am. By 11am he had delivered 2.5 cu.m concrete for Simon, Rob, Bob-next-door and me; but we had only installed 2/3 edging. Fortunately he was able to return later that afternoon to deliver the remaining 1.5m³. We used some of the excess to haunch the soldiers, but still I worried. At least the worst was over. Or so I thought... At 6.40am on Thursday, I awoke to hear a lorry outside the house. Nothing unusual, thinks I, we're on a fairly main road. Except this partiular lorry - driven by Elvis - had the first 10T of my DTp1 onboard. I invoked the standard delaying tactics of tea and 9-month-old daughter, but the load was tipped at 7.30am. 9am saw the second 10T. The 3rd at 10:15 and the last 10T was delivered at 11.30. By 4pm the whole 40T was installed and wacked into place. 3T excess was relocated to the back garden. TBC... Unfortunately, by Friday morning a more laid-back attitute had take hold. The 7T of 10mm shingle arrived at 11am and Rob and I (by now the only remaining labourers) had it shifted by 3pm, but somehow it seemed slack. Today (Sat) I mixed a bit of concrete to be the path's edgeing and laid out another of the pathways, but apart from that did very little. I hope to finish tomorrow. Photos to follow... Kind regards |

||||

|

Tony McCormack Mar 17th 2003 |

Sounds like you've been having fun, Neil! I know what you mean about the wagon drivers - if you're waiting for them, they don't land until 4 in the afternoon, but if you're struggling, they're on site before dawn has broken. They seem to think normal folk keep the same ungodly hours that they do - many of them load up the night before so they can be onsite even earlier, and grumble even more about 'being kept waiting'. I've never understood why they think turning up at 6am is a good idea - most sites don't start until 7.30 or 8am at the earliest!

Looking forward to the piccies - have you got a six-pack belly now? |

||||

|

|

|||||

|

Extending Drive - Eugene - Jan 30th 2003 | ||||

|

I intend to extend my drive width-wise and incorporate a right hand curve as you face the house.

How do I :

Would it be easier to use Keyform Edging as opposed to bedding and hauncing the soldier course?

help help help |

|||||

|

|

Tony McCormack Jan 30th 2003 |

||||

|

Hi Eugene,

I'm not with you on Q1 - what's the difficulty in making the area of extension tally with the existing? On Q2, if you're taking up an existing soldier course, you can use a length of timber as a temporary brace. Position the timber (a length of 100x50 or similar) so that's it's tight up against the exposed block edges, then use road pins or steel dowels to fasten the timber in place. Old sleepers make good temporary braces, too, and they don't usually need bracing. Try to keep any vehicles at least a metre away from the exposed edge for the duration, and get it re-paved asap. You may need to take up a half metre or so of the existing blocks to accommodate the new extension levels. |

|||||

|

Eugene Jan 30th 2003 |

Hi Tony

Thanks for the speedy response, I am a bit nervous about not getting existing and extended drive to level out evenly. |

||||

|

Tony McCormack Jan 31st 2003 |

Do you mean getting the surface of the extended area to tally/coincide with the surface of the existing paved area? | ||||

|

Eugene Jan 31st 2003 |

Hi Tony

Just as you put it, to tally / coincide with the surface of the existing. And many thanks for your help and inspiration so far. I feel confident to tackle this project in the spring. |

||||

|

Tony McCormack Jan 31st 2003 |

Once you've got your sub-base in, and you're preparing the screeded bedding layer, screed from the existing drive, running the screeder board over the top of the existing blocks to establish a bed for the new paving. You'll need to do a bit of tittivating, tidily feathering-in the new bed to match the existing blocks, but it's quite easy - honestly! |

||||

|

Eugene Feb 2nd 2003 |

Many thanks Tony.

I'll take before and after pictures to show you the result. Thanks for all the advice. |

||||

|

Eugene Feb 19th 2003 |

Is it possible to replace the old blocks (they are under a year old) with new ones to match the proposed extension?

Otherwise given that they are fairly new, can I alter the layout from the current strecther bond, to herringbone for extra strength, all this without having to go over the entire site with a whacker? |

||||

|

Tony McCormack Feb 19th 2003 |

I can't see any reason why you wouldn't be able to swap old for new, assuming they are the same size. You might be able to re-use the old blocks on another project elsewhere in the garden.

But, whether you re-lay the old, or replace with new, you're going to need a vib plate to do the job properly. Ideally, you'd partially compact the bedding layer before laying the blocks, and then you need the plate to consolidate the blocks and rattle in the jointing sand once the paving is laid. Were you hoping to avoid the hire charges? |

||||

|

Eugene Feb 19th 2003 |

Thanks for the reply Tony

Just wanted to make sure that I do the job properly. Get well soon, cause we all find your wealth of information and encouragement invaluable. Best regards |

||||

|

Eugene May 7th 2003 |

Hi Tony

The hour is nearly at hand. I shall start extending my drive next week, and wanted your help to finalise a few details. The contractor used 60mm Brett blocks which are of poor quality. 1) I intend to replace the whole drive including the extension with Marshall 50mm blocks (total area 35 sq m) There is a 10mm height difference between the drive edge and the pavement. This means that when I use the 50mm blocks, the drive will be slightly below the pavement level. How do I increase the height of the existing soldier course bedding in order to retain the existing level? 2) I intend to leave a 4m by 4m sqaure lawn to one side. What is the best point to start trimming the blocks to achieve a 'sweet' bend around one corner. |

||||

|

Tony McCormack May 7th 2003 |

1 - Replacing 60mm Bretts with 50mm Marshalls - are you using the existing Soldier edgings? A 10mm diff can be taken up be adding extra bedding sand, but if you're lifting the soldiers, too, then they should be bedded on an additional 10mm of a Class II mortar, to ensure they're held firmly in place.

2 - Eh? Do you mean you're having a lawn with a 4 metre radius? I can't follow what you mean! |

||||

|

Eugene May 8th 2003 |

Thanks for the speedy response Tony

I will replace the existing soldiers as well. How do you achieve a class II mortar mix? The total surface area of the lawn 16m sq (4m X 4m) the soldiers will run along two sides of the square to form the curve, i.e as you approach my house, the drive will bend to the right along the two edges of the lawn. I hope I am making sense to you and thanks for having the patience of a Saint for us. Regards |

||||

|

Tony McCormack May 8th 2003 |

The 'recipe' for a Class II mortar is given on the Mortars page. Basically, it's a 3:1 mix.

As for your lawn edging, if you've a 4x4 lawn, then the size of radius you choose is a matter of personal taste. Using a 4m radius would take a big chunk off the lawn, but would give you a nice, easy turn. A 3m radius is a good size for a private driveway, and owt faster than around 2m radius is uncomfortable for vehicles, but OK for pedestrians. If it were down to me, I'd go with a 3m radius. |

||||

|

Eugene May 29th 2003 |

Hi Tony,

I am in need of help badly. I tried to mitre a corner instead of creating an arc, however, the second mitre goes out of square. Any help? I am close to becoming a laughing stock in the neighbourhood. Regards |

||||

|

Tony McCormack May 30th 2003 |

Help with what, Eugene? Can you explain?

If it's help to ensure the setting out is 'square', then you need to use the 3-4-5 triangle trick, as explained on the Setting Out Construction Lines page. If it's help with summat else, you'll have to give me more info. |

||||

|

Eugene Jun 1st 2003 |

Hello Tony

I was worried at the time, and as usual its always best to sit back and use the grey matter a bit. The problem was I got the first mitre to swing my row of blocks 45 degrees to the right, however, I couldn't get the second mitre to swing the rows to swing another 45 degrees to the right, thus obtaining a a 90 degree turn, at the same time ensuring that the row run parallel to the front of the house. I used the 3-4-5 to obtain a true parallel with the front of the house, then adjusted the angle of the second to compensate. This seemed to work, and looks really great. I can't thank you enough for a wonderful site, will send you some pictures. Many thanks once again. Regards |

||||

|

|

|||||

|

Filling gaps on a "convex curve" - elessar - Feb 3rd 2003 | ||||

|

Our concrete block driveway is horizontal at the top alongside the house, then slopes downwards to the road. It's a normal herringbone pattern. Where the slope angle changes, the gaps at the top of the blocks are obviously larger (I don't know if they could/should have been chamfered to a tight fit, but they are not) and rain washes the sand out. The gaps are maybe 3mm - 5mm or so at the top of each block, for a row or two.

Is there any reason not to refill the gaps with weak sand and cement dry mix so it sets hard and doesn't wash out? |

|||||

|

|

Tony McCormack Feb 3rd 2003 |

||||

|

A 3-5mm gap is nothing! Don't be making a mess of the blocks by using a cement-bound jointing material. It won't last more than a season!

Just use normal jointing sand and, within 3 months, it will have crusted over with natural 'crud' and will seal itself. If you have any problem with 'scour', then use Keybond or similar to stabilise the sand in the short term, but, I can more or less guarantee that, by this time next year, you'll not even notice the slightly wider joints. Incidentally, just how severe is this change of direction to create joints that are noticeably wider than normal? Most 'rollovers' only widen the joint by 1-2mm. |

|||||

|

elessar Feb 3rd 2003 |

It's been down for five years! I fill in the gaps with kiln-dried sand once or twice a year but it washes out. Maybe I underestimated the gap size; I'll take some photos and post a pointer; it's quite a steep angle change which couldn't be smoothed out much because of a sewer pipe. | ||||

|

Tony McCormack Feb 3rd 2003 |

If it's 5 years old, then this is an ongoing problem, and you should treat it with a joint stabilising compound, as mentioned in my last message, or look to seal the entire pavement with a decent urethane-based sealant. I'd still like to see the pics, though. |

||||

|

elessar Feb 4th 2003 |

Thanks! Pics are:   - and the gaps are wider than I first estimated - 10mm or more. It also can't help that the car is turning on full lock as it goes over this area. I'll try Keybond. |

||||

|

Tony McCormack Feb 4th 2003 |

Nice measure! Yes, try Keybond or WJC from Resiblock. That should eliminate the problem of scour. It's probably worth cleaning the pavement first and topping up the joints with fresh, genuine jointing sand before applying one of these stabilising compounds. Let me know how you get on. |

||||

|

|

|||||

|

Block paviors for walls - Michelle Anderson - Feb 4th 2003 | ||||

|

I want to build a patio which will be cut into a slight slope and would like to use clay block paviors as a low retaining wall and as the risers for my slab steps.

Is this a good idea, if so , any tips on best way to build would be appreciated! |

|||||

|

|

Tony McCormack Feb 4th 2003 |

||||

|

Block pavers are designed to be used for paving, rather than walling. Although there's nowt to stop you using them for a low-level non-critical wall on your own property, I wouldn't recommend it for a number of reasons....

...but, as I said, it's you that has to live with it, and if that's what you want, then there's nowt to stop you. My advice would be to use as stiff a mortar as possible and to lay them on a decent concrete footing, as shown in the brickwork section of the site. |

|||||

|

|

|||||

|

Rigid or Flexible Construction - Lightning - Feb 8th 2003 | ||||

|

|I have been getting quotes from a number of companies to look at paving my drive, and was half contemplating doing it myself, the problem is the companies whose work I went and looked at and I am happy with, insist on only laying pavers on a concrete base. They claim they dont want to be back in 3-5 years fixing problems.

From reading through your site I assume this is 'rigid paving'. Is this overkill and not warranted assuming the drive will at worst carry a 4WD or a truck tipping topsoil for landscaping etc? Any advice appreciated. |

|||||

|

|

Tony McCormack Feb 8th 2003 |

||||

|

It seems that Rigid Paving, which is what you're talking about, is more popular in Oz and the US than in Europe, and Britain/RoI in particular. Over here, more than 95% of all Block Paving is flexible construction and although it is reasonably problem-free, we do see settlement and rutting on some poorly constructed works, but then, we see spalling and bricks coming loose with rigid paving that is subjected to vehicle overrun.

Flexible construction is simpler, cheaper and faster than rigid paving, and so it grabs a large slice of the European market on cost grounds alone. Rigid paving is not often specc'ed for residential driveways, even those taking slightly heavier-than-normal vehicles, such as you describe. Assuming you have a reasonable sub-grade, most British/Irish contractors would specify flexible paving, possibly using a geo-membrane between the sub-grade and a 150-225mm thick sub-base, and, assuming it was properly laid, there should be no problems for 10-15 years, ne'er mind 3-5 years. But, as some acronym-lover once said, YMMV, and it's always best to follow local advice. If the local tradition is for rigid paving, then go with it, but it's probably worth getting a quote for flexible construction, just to see if it's any cheaper. But to answer your question directly; I would say that rigid construction is overkill for the project you describe. |

|||||

|

Lightning Feb 9th 2003 |

Thanks for the quick and detailed reply I still have a fair bit of time to look into it, so I will do a bit more investigation and see what turns up....

Feb 17th 2003 I have decided to give it a go myself, but I have one other small area to deal with, the entrance to our block was just a spoon drain so I had to make a driveway to it (I think its called a table crossing?) Anyway it basically consisted of a bloody heavy pipe with concrete headwalls(which were also bloody heavy!!). I dug a trench to create a crushed rock bed under the pipe then spread a further layer (about 120mm) above the pipe which is now compacting nicely). My problem is there is only limited room to add aditional rock to form a thick base as the land slopes down towards the driveway and I dont want to end up with a hump or a lip before reaching the road. (excuse the artistically challenged diagram)

Should I attempt to add more rock and compact it and possibly build the property side up to allow for a thicker layer, or should I look at using concrete/bitumen for the crossover piece and only pave the driveway itself. We are building a home atm so I wont be paving straight away, I plan on leaving it as just a rock crossing till the have poured the slab, I am assuming the pipe wont compact any further than where the truck pouring the slab will flatten it too. thanks |

||||

|

Tony McCormack Feb 179h 2003 |

How feasible is this.....?

...would it be possible to use a concrete sub-base over the pipe in place of the more usual granular material? I've shown the concrete sub-base extending 450mm beyond the excavation limits of the pipe trench, but actual site conditions may vary. You could also use a 'hogback curve' to accommodate the levels. This involves a 'hump' over the pipe, rather than a flat bone from the top to the bottom of the drive. With a bit of careful setting out, this can actually look quitre natural and intentional - there's more about hogback curves on the Profiling page - take a look at the sketch for a transition ramp, which is the sort of thing I have in mind. |

||||

|

|

|||||

|

Membranes - Tigg - Feb 12th 2003 | ||||

| I am about to lay a 125mm sub base direct onto clay prior to block paving and have been advised to lay a (weed prevention) membrane under the hardcore first. I am unsure as to whether this would have any benefit. A colleague said he has just had his drive block paved and a similar type of membrane was laid between the sub base and the sand top dressing? | |||||

|

|

Tony McCormack Feb 12th 2003 |

||||

|

There's a subtle difference between 'weed membranes' and geo-sheets. The former are intended to keep out the dandelions and the like from gravelled areas, while the latter are a structural layer performing an important function within a pavement. You might use a geo-sheet at the boundary between the sub-grade and sub-base if there was a problem with the condition of the ground, but there is rarely any need to install a weed membrane beneath a block pavement that has a 100mm sub-base. The one exception is when there are pernicious weeds, such as Equisetum spp (Mares Tails) or Polygonum spp(Japanese Knotweed) and even then, I'd much rather specify a geo-sheet, on grounds of inherent strength, than a weed membrane.

99% (roughly) of weeds can not grow through a properly constructed block pavement, but even a weed membrane will not stop them growing into a block pavement, anchoring themselves in the sand-filled joints. Weed membranes are, in almost every case, an utter waste of time and money when used beneath block paved residential drives and patios |

|||||

|

Tigg Feb 12th 2003 |

Have just noticed all the other pages on the site re the block paving forum, and I think now that I've seen the other replies on this exact subject (don't know how I missed them) I shall keep my pennies for a bottle or two when I've done the drive. | ||||

|

|

|||||

|

Compacting in cold weather - Steve R - Feb 14th 2003 | ||||

|

The weather forecast for the coming weekend is without pissipitation so I am hoping to take full advantage and block pave a 17 square metre circle. The kerbs and soldiers will be bedded on Saturday and the circle paved. The kerb mix is very dry, but as the overnight temperature is going to be below freezing should I add an anti-freeze?

Will it be ok to compact and sand the blocks on Sunday if I keep away from the soldier course? Thanks |

|||||

|

|

Tony McCormack Feb 14th 2003 |

||||

|

Hi Steve,

most ready mixed Concrete companies will add an anti-freeze to their concrete if they anticpate temps of below 4C and falling. If you have the concrete delivered at, say, 10am on Saturday, and it's a typical semi-dry kerb mix, you should get a good 4-6 hours working time with it, and have the kerbs laid and haunched before the temp drops significantly, but it's probably still worth checking what the supplier recommends - they're far more 'in touch' with the local weather than I am. Normally, though, on residential works, the end strength of kerb mix isn't a major concern - as long as it 'sets' and doesn't fall apart, it'll do, and so anti-freeze isn't normally added. If you cover the exposed concrete with sand, hessian or summat like that, it will help keep the worst of any frost off the concrete while it sets overnight. Come Sunday, I reckon you should be ok with the compaction, as long as the kerbs are held in place with the lower soldier course, as previously described. Don't go mad with the vib plate - you can get a basic level of compaction, enough to consolidate and rattle in the jointing sand, and then go over it again in a week or so, once the rest of that paving is in place and providing full support to the kerb. |

|||||

|

Simeon @ Ronacrete Feb 19th 2003 |

If you want to be sure that the strategic blocks are well bedded and secure, use a bedding mortar designed to work at low temperature.

Monoset RX will do it down to -10C, pot life once (hand) mixed is 10-15 minutes. Bed depth 6mm-50mm. The liquid polymer ensures it sticks. Bed it onto concrete with Monoset Primer. See the PDF File on our company website for more information |

||||

|

Steve R Feb 21st 2003 |

Thanks for the advice Simeon, fortunately saturday night was frost free and all went well.

|

||||

|

Steve R Feb 21st 2003 |

Hi Tony

The extra pack of Beta blocks came in yesterday afternoon. Brett have excelled theirselves a change from my previous dealings with them. So it's away with the mixer at the weekend. The bxxxxx badgers have decided there may be worms under my circle and have removed some of the soldiers and dug out some of the haunching.

Q: |

||||

|

Steve R Feb 22nd 2003 |

Hi Tony

The circle is finished! Fortunately the sun came out dried the blocks so the sand flowed well. The cutting took quite a time but if I hadn't taken your advice to make the cuts on the inside of the circle it would of taken even longer. Also got about 10 metres of land drain in with another 10 for tomorrow. |

||||

|

Tony McCormack Feb 23rd 2003 |

Progress at last, Steve! With your kerb, try to keep the upstand, that is, the amount of kerb sticking up above the paving level, to no more than 125-150mm. Most road kerbs are set to this level, as it minimises damage to wheels and tyres, and ensures doors opening aren't bashing against the kerb.

There's nowt to stop you having, say, 185mm of upstand, if you want, and as long as the kerbs are bedded and haunched as shown, they'll be fine. |

||||

|

|

|||||

|

Heavy Application & Laying for Interlocking Clay Pavers - Rajpal - Feb 15th 2003 | ||||

|

Dear Sir,

I have located your site (a wealth of information) and am in the process of going through you contents. Well this comes from INDIA and we are manufacturers of clay pavers, machine made bricks, cladding and terrace tiles all made using highly compressed clay. Our products have been tested for compressive strength and are >80 tons. This question is primarily aimed at Heavy Duty Interlocking Clay Pavers i.e. 230 (Length) x 115 (Width) x 75mm (thickness). We have been given an opportunity to lay our products as a sample free of cost on a test trial basis. The useage is in a container depot wherein heavy trailers carrying 40 feet containers i.e total weight of about 60 tons and heavier cranes of about 80 tons are being used. They have earlier been using concrete pavers of 8 x 4 inch dimensions with 100mm thickness. 1. My question here might sound absurd but have clay pavers been used in heavy applications as outlined above. If so could I get a reference to quote. 2. We as manufacturers have been told to layout about 1000 sq. ft. in two of the heaviest usage sites to be throughly tested. Only to lay the pavers and a 50mm sand bedding. (Is there a special way to do this, if so what would be the best alternative, given the fact we have no machinery or tools to do the job except for an ordinary maison). What we had planned is take the patch and put 50mm sand and flatten it and lay my pavers (with no joint gap other than the natural gaps) and put fine dry sand over the pavers to fill the gap. The client has already done an excelled job on the sub-base. 3. The concrete pavers being used have about 12mm of sand in between them and the bedding of sand is about 50mm. My clay pavers have bevelled edges and being interlocking will not have a gap of 12mm, in some cases negligible and in some cases 4 to 10mm due to slight shrinkages in the material having been fired at different firing zones (we have a high draught coal based brick plant). The products have been made on a an imported plant from Australia. Will providing a forced gap of 12mm filled with sand, aid in futher cushioning or is not required. The ground where they are to be laid has excellent sub bases and sub grades over 3 feet base fortified. 4. What size of the paver would you suggest to use in such heavy application areas. This is a one chance to get our material passed else we simply do very small quantities of pavers for driveways. The market in India is totally unaware of the usage of clay pavers with sub-standard concrete pavers gaining momentum in government contracts. Appreciate you sharing/shedding your knowledge on the above and I will definitely go through your side in the interim. Many thanks and best regards...Rajpal |

|||||

|

|

Tony McCormack Feb 16th 2003 |

||||

|

This is a complex series of questions, Rajpal, and far beyond the sort of request normally submitted to this forum. To be honest, you need the services of a civil engineer, one with several years experience in the paving industry, to advise you, as your trial pavement needs a specific design to ensure best performance. As this is such an important business oppoortunity for your company, I would suggest the consultancy fees for bringing in such a specialist would be a wise investment.

Anyway, to briefly answer your questions.... 1 - Clay pavers in HD applications - You could try reading "The structural design of heavy duty pavements for ports and other industries: 3rd edition" from the British Ports Association and also "The use of pavers for Aircraft Pavements" 1996 from The Civil Aviation Authority. 2 - laying the blocks - assuming you opt for a flexible construction, then the basic laying method outlined on the Laying Blocks page would be the way to proceed. 3 - jointing - a 12mm joint is excessive and will be a weakness in the finished pavement. You need to limit joint width to 2-5mm and rely on sand joints to generate sufficient inter-brick friction to spread the loads imposed on the finished pavement. 4 - paver size - depending on the lab results you're receiving for compressive and tensile stengths, I'd guess that you'd need to provide an 80 or 100mm thick paver. Typical plan size for British clay pavers is 200-215 X 100-107 X 65/80mm, and there are standards (BS6677) governing dimensional accuracy and required minimum strengths. I'm sorry I'm not able to give comprehensive answers, but what you're asking is highly technical and beyond the scope of the free service I provide in this forum. I strongly recommend you get yourself a professional consultant. |

|||||

|

|

|||||

|

Block Sealing - Mr Block - Feb 18th 2003 | ||||

|

I have a drive recently block paved with Marshalls Tegula Penant Grey blocks. I prefer the darker colour of these blocks when they are wet.

I was wondering if I should use Resiblock Superior sealant to protect the blocks and perhaps give me a darker colour when they are dry. However the Marshalls technical department say that they do not recommend any sealants because of the uneven sealant wear caused by car tyres.

Any views on the this wear aspect, and will the Resiblock Superior darken the penant grey blocks? |

|||||

|

|

Tony McCormack Feb 19th 2003 |

||||

|

Marshalls are correct in what they say about wear on the sealant, especially on those driveways where you access the same spot day after day after day, creating two parallel tracks, but it's relatively simple to re-apply the sealant if the wear becomes very noticeable. It's also worth noting that Resiblock Superior is one of the best sealants in the world, and not as prone to wear as some of the acrylic sealants. I reckon, judging from experience with this sealant, that you should get at least a couple of years before you start to notice any difference in wear.

If I were you, I'd do it. |

|||||

|

Mr Block Mar 4th 2003 |

Thanks for the advice Tony. Since the blocks have only just been put down I have a few months to think about it! It might make up my mind if I could see a Marshalls tegula type block drive that has been treated with Resiblock Superior and that has been down for a year or two. Does anyone know of one, preferably in my area, South Northamptonshire? |

||||

|

Tony McCormack Mar 4th 2003 |

Have you asked Resiblock? They might know where their products have been used on a commercial project in your area. | ||||

|

Mr Block Mar 4th 2003 |

Resiblock said that some McDonalds had been done, but they could not be specific about which ones. Otherwise they suggested I contact block paving contractors in my area. | ||||

|

Tony McCormack Mar 4th 2003 |

Most of the MackieD's are done with PIC, not with Tegula Pennant Grey. It's some kind of 'corporate architecture' hangover from their spiritual home in the US.

Well, if Resiblock don't have any contact details, then all you can do is ask around the local contractors, or call in at your local BMs to see if they sell the Resiblock and, if they do, who they sell it to - that might get you somewhere. I had a look through my photo library but I don't have a single piccie of any form of Tegula or Drivesett that's been treated with a sealant. Odder still, I don't ever remember seeing a Tegula Pavement that's been sealed, or I would have tried to get a photo, if only for my own interest. |

||||

|

Mr Block Mar 4th 2003 |

Thanks for the prompt replies Tony.

The contractor who put my blocks down said he would be interested to see the results of sealing too. Incidentally, Resiblock recommended a first coat of 22 applied with a squeegee, followed by a coat of Superior, to reduce the chance of sand "pick-up" with this type of block. I will do as you suggest starting with with the BMs. |

||||

|

|

|||||

|

|

|

|

Brew Cabin Archive navigation dhtml courtesy of Milonic |